Pictures coming

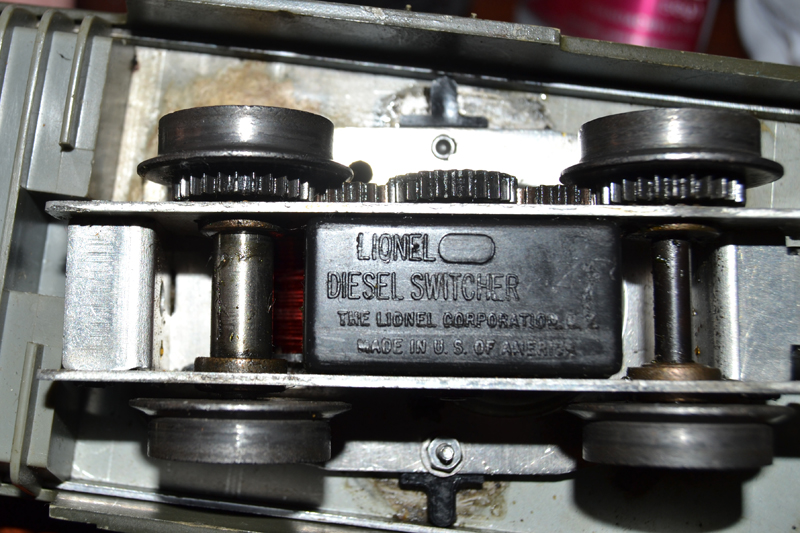

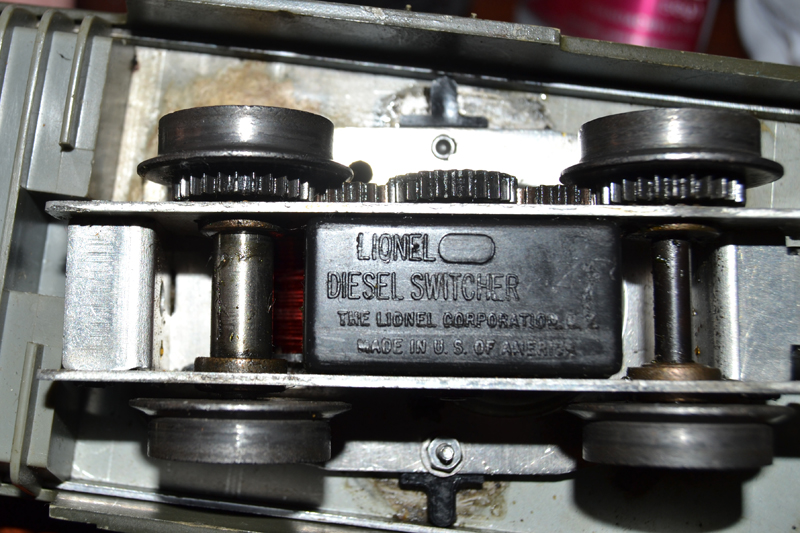

Lionel Pullmor engines can run very well, once you eliminate the problems

of dirt, corrosion and wire insulation deterioration.

Soldering skills are needed.

When I buy Postwar, I make sure there are signs of light wear.

About 60% of the time they wont run well and need cleaning and replacement

of wires that have rotted insulation.

Cleaners

WD40 is NOT a good cleaner. It was designed as Water Dispersal for the Atlas rocket, to keep it from rusting. It will leave a film behind that you do not want. Neither is WD40 designed to be a lubricant, nor penetrating oil.

CRC electronic contact cleaner. Good if you are not going to disassemble the motor. I would keep it off of plastic and paint. The old paint may not like it.

Mineral Spirits. I use odorless mineral spirits. A tablespoon/40grams worth is all you need for a lot of cleaning.

Oils

I recommend strongly, modern plastic friendly oils. They may seem expensive, but the small amounts used per engine makes them last for years. Labelle and Excelle Lubricants, XL, are the brands I use. There are multiple types. Light to medium for axles and thicker gear grades to stick on the gears themselves. There is also synthetic grease that is needed for the "gear box" or worm gear areas in some engines.

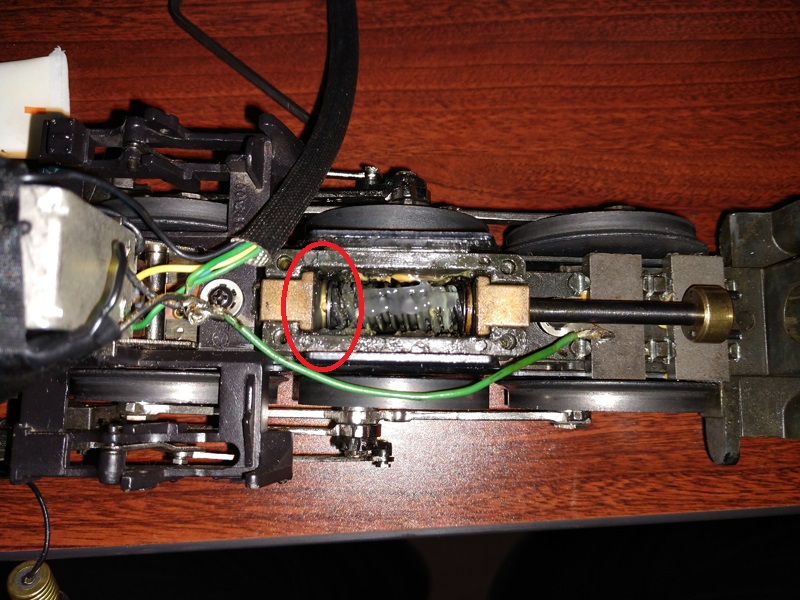

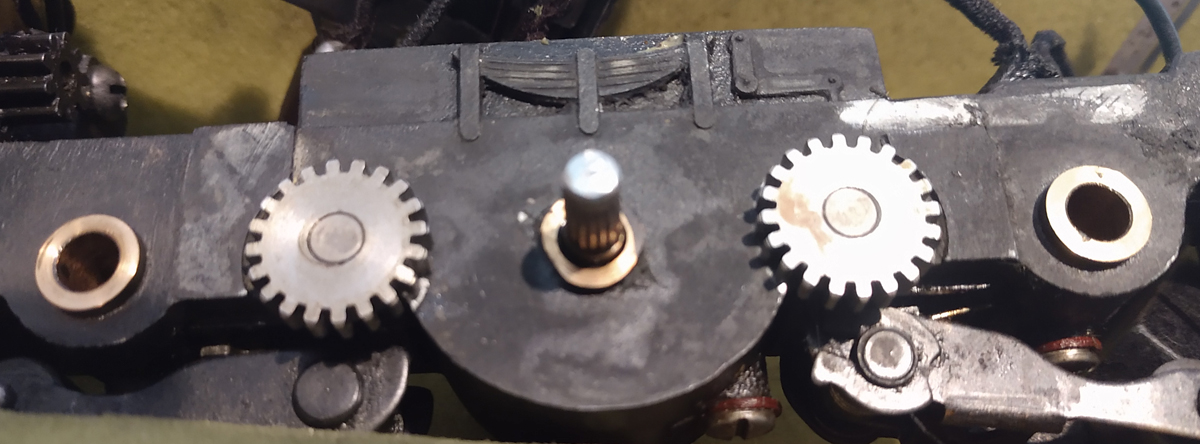

Gear box where grease is used. Usually where there is a "worm" gear.

Thorough cleaning requires disassembly

The primary cause for poor to no running is the brushes have gunk build up holding them in place. Or the commutator on the armature has a lot of gunk. What causes this gunk? Carbon buildup and over-oiling. Too many people think oiling where Lionel did not intend oil to be fixes everything, but it makes it worse. When I take the engine apart, I take off the brush plate from the motor. This may require some soldering of wires. A little mineral spirits on a Q tip. Clean the commutator. Careful only on the top, don't wash down the wires with mineral spirits. It may loosen the lacquer insulation on the wires. Then wipe dry. Use a round tooth pick to make sure any gunk is cleaned out between the commutator plates. Then very fine sandpaper to lightly sand the plates, or a rush eraser to clean the plates. It should look similar to this when done.

Now clean the brushes themselves and the brush holder. Cotton swabs work to get inside the brush holders to clean after dipping in mineral spirits and then dry with a clean swab. Make sure you don't leave cotton threads behind. I soak the brushes for about a minute in mineral spirits and then wipe dry. Make sure all the gunk is off the tips of the brushes. It may take multiple Q tips when really dirty. Make sure it is all dry and put it back together.

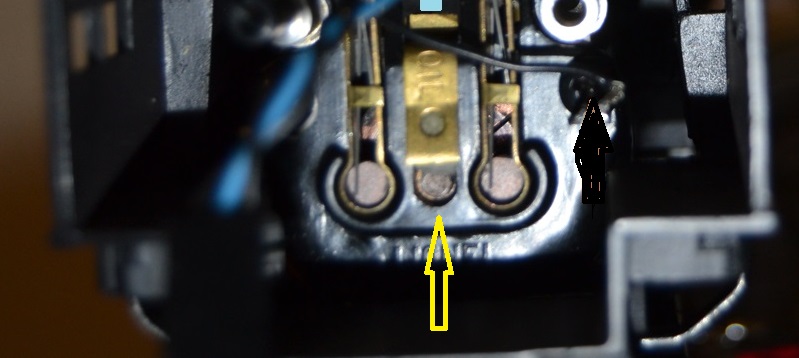

Oil only 1 small drop where the armature comes through the brush plate. and the other side where it contacts the gears. Diesels may be harder to get to this side for oiling. Some designs have a felt pad to hold the oil on the contact plate. Make sure the felt pad is pushed down and lightly contacts the armature shaft. Then oil the felt pad at the hole or top, just a drop or two. Top of a motor with the felt pad and Oil hole. Yellow arrow points to armature shaft.

Then Oil each wheel on the inside at the axle bushing. Many of the steamers have notches in the pickup plate so you can get to the axle at the bushing to oil it. One drop, not much is needed. Also oil the pins the idler gears ride on with light oil. Idler gears are the gears between the main drive gear/motor gear and the wheels. Light so it soaks in. Then a light coat of gear oil on the gears. Diesels also have gears connecting the drive wheels to the main drive shaft. Same procedure for these. Only a few drops for all the gears. On diesels with a worm gear from the motor to the main drive shaft, a synthetic gear grease is recommended.

This picture shows Gears on a diesel unit. The axle bushing area is easy to get to to oil also.

Idler gears. Make sure the pins they run on are not loose or flopping around. If loose they cause excessive gear wear of binding.

Linkage

There are two types of drives for the wheels on steamers. The first type is all the drive wheels are gear driven. The linkage rods on these type of steamers are for show and only light oil is needed to make sure they don't bind. The second style of steam engine is one set of drive wheels is connected to the motor and the others are driven by the main drive rod. No idler gears or gears on the wheel. The Turbines, Berskshire and scale Hudsons run this way. The linkage needs to be checked for excessive wear and make sure the main drive rod is oiled correctly at each wheel connection.

Wheels

The wheels may have a build up on them where they run on the track. Even the non powered cars may have a buildup. It can interfere with grounding of the wheels. It may require a small flat bladed screw driver to "pop" off the thicker layers of gunk. Then clean with swabs and mineral oil on the rail contact areas of the wheels. Make sure to wipe dry. One wheel may look clean, while another may have a lot of buildup, check them all.

Picture of buildup that has been removed, about .010"/.25mm thick that has been scraped off non-power wheels on a postwar boxcar. It was thicker at the corner of the wheel and flange. Enough build up may lead to derailing problems.

Wires

Age of the wires may cause the insulation to become hard and brittle. In some cases it is so bad, moving the wires causes the insulation to crack and fall off. If you see cracks in the insulation or when you bend a wire, the insulation cracks, replace the wires. Take multiple pictures before you start. So you don't get the wires wrong on re-assembly. There are supplies that have same style and condition of wires.

I have found that new shrink wrap tubing of the right size can be used to replace the insulation when replacing the wire is too much of a problem. The 3656 cattle car is an example, Shrink wrap can slide down to the coil so you don't have to remove the coil box to replace the wire. Usually I just replace the wiring when both ends are accessible.

Stiff insulation or stiff wires are a problem on the wires going to the center rail pickups. Primarily on the center rail pickups on lighted cars and 5th rail pickups for operating cars. If the wire doesn't flex, the wire will break during use. I usually replace the pickup wires if they are not still very flexible. A multi-strand, flexible wire should be used.

E-Units See the E-unit page

Smoke Units

The old pellet style smoke units can last a long time. I find that

many previous owners got too anxious and overloaded the unit with

pellets. Same thing with the liquid smoke units. When I

carefully take them apart, the packing filler under the resister coil

itself is a blob of hardened waxy goo. I take out the old packing

and throw it away. Clean the unit, put in new packing and put it back

together. A thicker packing helps when smoke fluid is being

used. Warning, this is not easy to do if you are trying to avoid

damaging the resister coil. You will have to replace the resister

coil if it gets damaged. I even had an engine that someone had

used motor oil in. The smoke could make you sick. Took apart

the smoke unit, cleaned it, new packing and it worked like new

Back to Main page.

Last update April 8, 2023