In work

I love the old 0-6-0 and 0-4-0 switchers with their slope back tenders. There was the 0-4-0 engines with their short slope back tenders and the 0-6-0 engines some with short slope back tenders and the top line 0-6-0 with their long slope back tenders.

Magic Electrol

Magic Electrol had a small relay that activates from the "horn" button. It required another, or 3rd wire from the engine. When activated it would ground the E unit causing it to cycle. To use the Magic Electrol correctly, the E-unit switch on the engine was in the "off" position.

Teledyne

This used a small relay in the tender, but in this case it connected 3rd rail power. It was connected into the 5th rail wire for the coupler that went to the engine.

Cast Engine for 0-4-0

Some of the O-4-0 engines came with a cast engine frame. They are noted below. It mounted with the slot in the front and a Screw hole in the back. The Prewar 229 also used this engine, but it did not have a tapped mounting hole in the back. Also the wiring to the E-unit on these was a little different. One brush had a ground to the casting and the other an E-unit wire. 2 Wires from the E-unit went to the field. The field switched polarity when the E-unit cycled, not the armature.

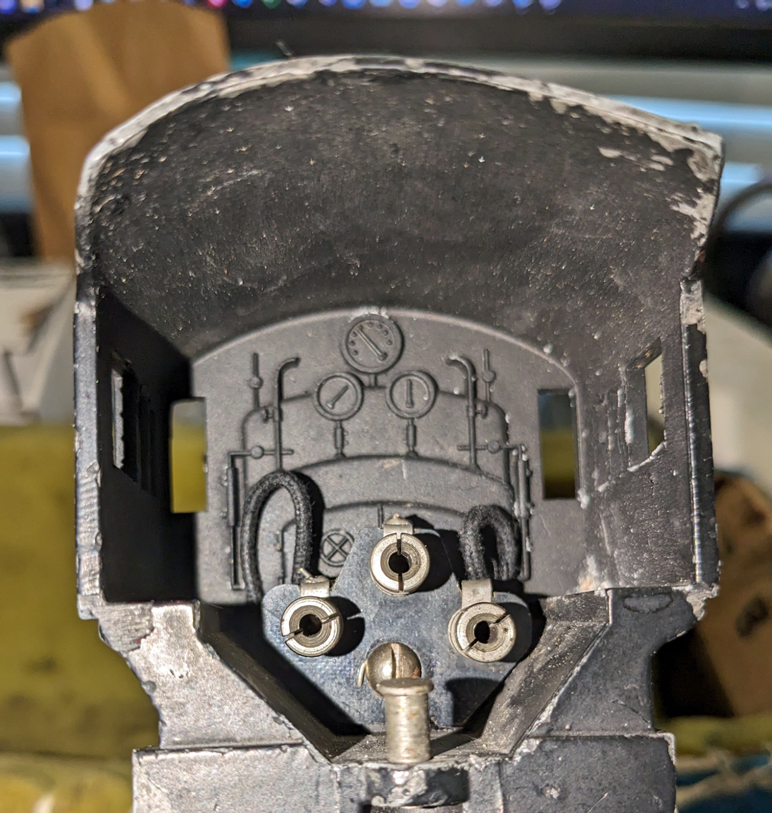

The Cast Engine frame and motor, front to the left.

2 or 3 Plug connectors

These engines had 2 plugs in the back of the engine. The left engine for engine coupler connection. The middle for power to the tender on Prewar locos. On postwar locos the middle was a ground.

There was an optional 3rd, right, plug. This was on engines with Magic Electrol connections. It connected to the E-unit relay wiring ground.

Pre-war 3 plug connection with magic electrol. Middle plug is power.

This is a postwar 2 plug. The middle is grounded.

The Pre War engines with a short slope back tender.

All had a left wire connecting the 5th rail pickup from the tender to the engine for front/rear coupler activation. These engines had a post for connecting the tender.

Pre War 0-6-0 engines with Long slope back tenders.

All had a wire connecting the 5th rail pickup from the tender to the engine for front/rear coupler activation. All had a horizontal engine with roller pickups similar to the 700e/763E.

For repair of the 227, 228 and 230-233 engines see the 228 repair notes. These engines are similar except for front coupler height. the front boiler number and the number of plug ins on the motor brush plate.

Pre War with 0-6-0 Scale couplers

Postwar engines with a bell ringing tender.

These engines had 2 plug ins. Left for the coupler, middle ground. These Engines had

Notable things

The 1662 and 1663 engines do not run through postwar switches and some control switches with the magnets well. The wheel diameter is slightly smaller causing the flanges to bottom out and bump through switches. The smaller diameter wheel also causes the geared wheels to bump at the magnets on postwar controller tracks. A workaround for this is to use an engine from a 1656, or switch out the drive wheels with drive wheels from a 229 engine that uses a similar cast motor.

The 1665 may also have problems bumping on the magnet area of a postwar controller track. The controller tracks with magnets where not made until a couple of years after the 1665's production. It is the gear on the inner wheel that catches. Carefully trimming the overhanging plastic at the top of the magnet may help eliminate the problem. Don't cut into the coil!

The prewar 1662, 1663, 201 and 203 had a Power plug for the middle plugin. Their tenders did not have a 3rd rail pickup. The postwar 1656 and 1665 had a ground connection for the middle plug. Their tenders had a 3rd rail pickup. Many owners switched it to a power plug and connected the wire in the tender to the 3rd rail pickup. To better to get through switches. No matter, always check to see if the center plug on the engine is ground or power. 0 ohms to ground vs. 0 ohms to 3rd rail.

The plugins on the 227, 228 and 230-233 engines may be a hole in the brush plate or may have standoffs for the plugin. Initially it was a hole and later production the standoffs were added.

The correct light bulb must be used. If it is too tall or too big of a bulb the shell will not fit. It is a 1449 14V clear bulb.

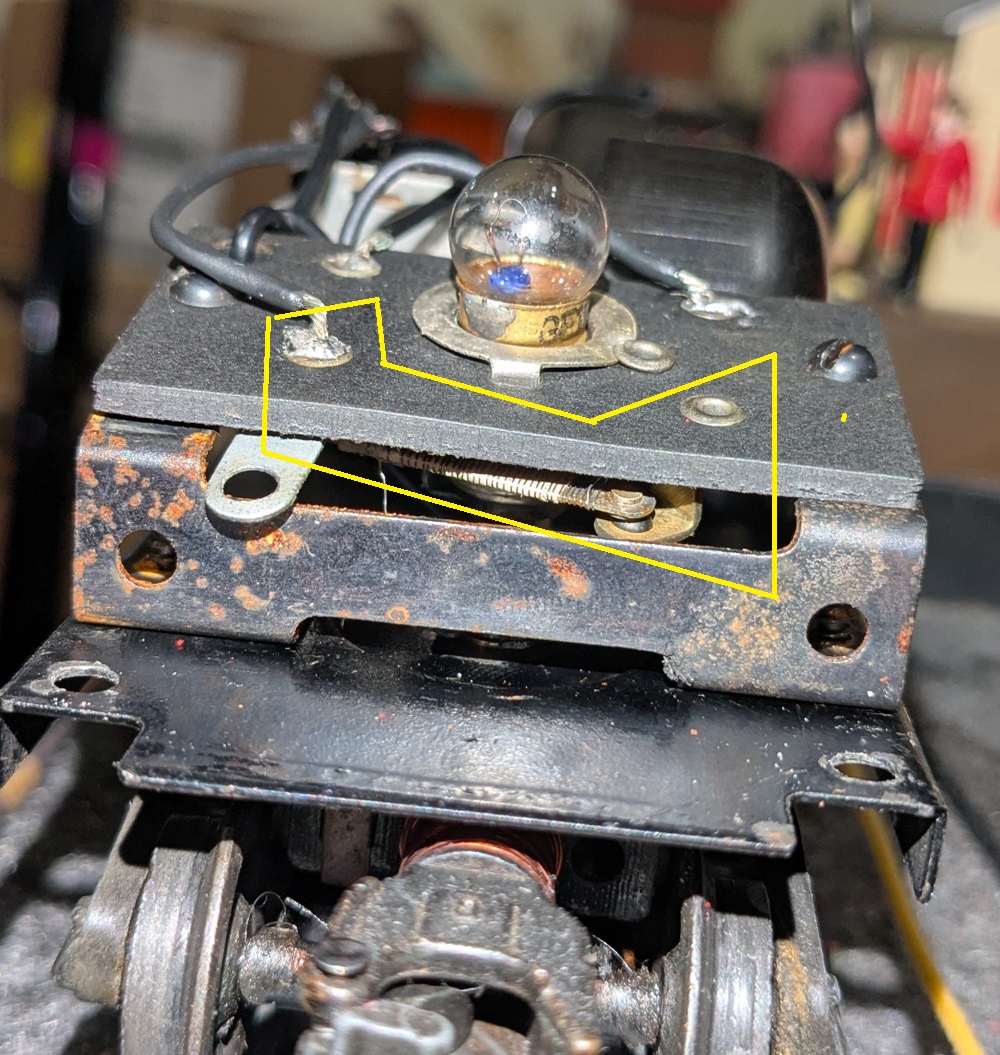

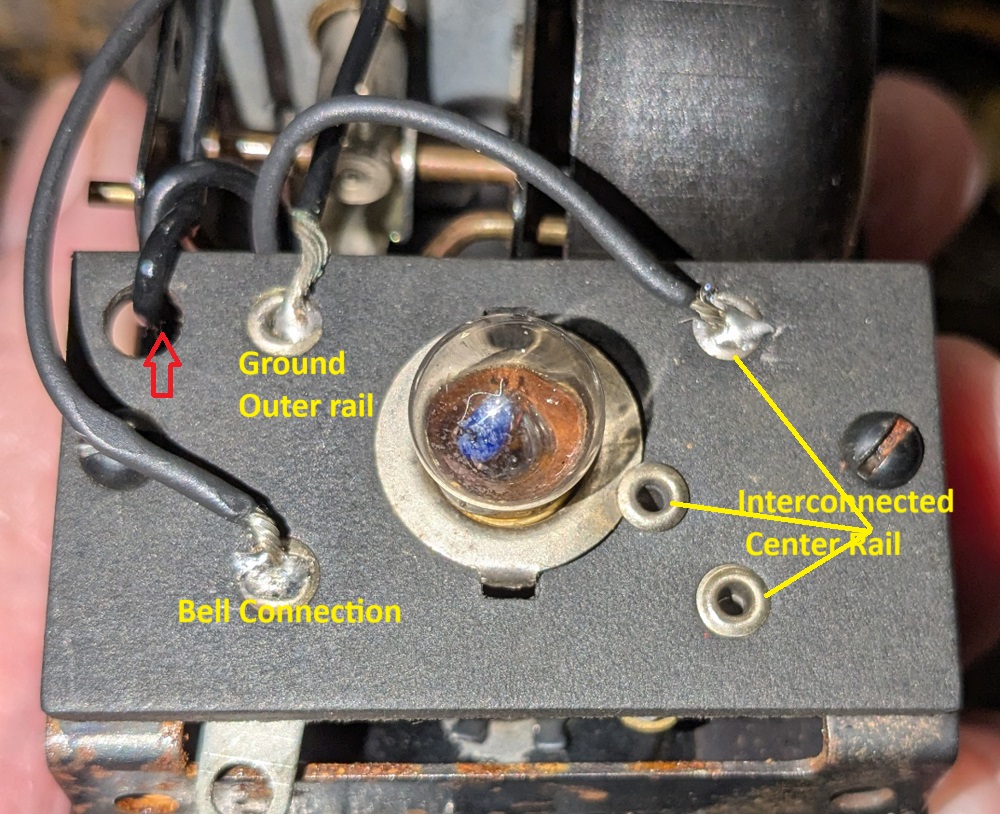

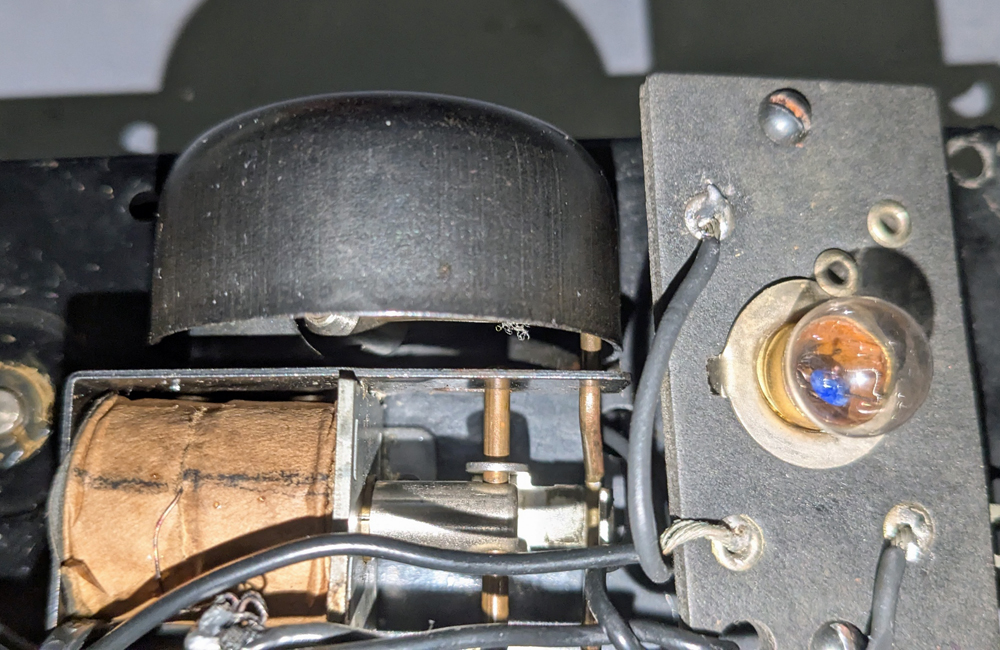

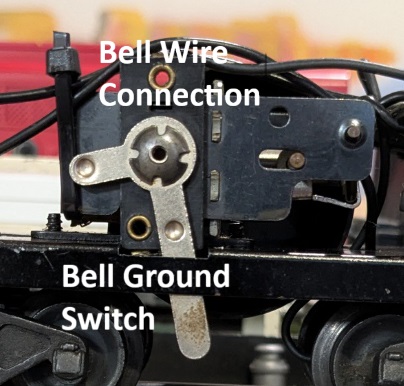

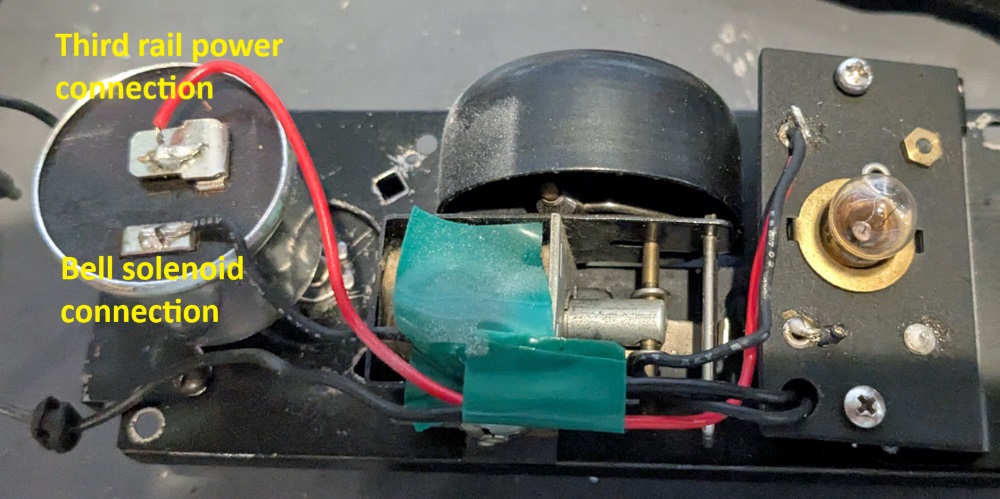

Wiring and Repair of the Bell Ringer

The wiring of a bell ringer can be confusing. That is because the socket for the light bulb is hot or 3rd rail power, not ground as normal. The bulb tip is connected to ground. At the back of the tender is the light board. The thermal switch that controls rate of bell ringing is mounted under this board. The bell connection goes to the relay for the bell. The other switch on the bell assembly similar to an E-unit switch is to ground the relay. If this is off, their is no power flow through the bell assembly. The thermal switch is always connected to ground and is always working when there is power.

A view of the thermal switch and 2 of the 3 connection points.

The Ground, outer rail connection is to ground the light bulb.

The hole in the top left of the board is often used to locate the wire that plugs into the engine and connects to the rear coupler and 5th rail shoe for the coupler. On my tender there is also an unused tab at the bell connection. I don't know what it was intended to be used for. It could be an old method for connecting the wire. The bell connection is where the thermal switch is attached on one end. The switch part of the thermal switch is attached to the bottom right rivet.

The ground or outer rail connection also connects to the left bolt as shown with the view from underneath that can be seen below. It also shows the 3rd connection of the thermal switch, the thermal wire ground. It gets the hot or 3rd rail power where it is connected to the contact on the other end.

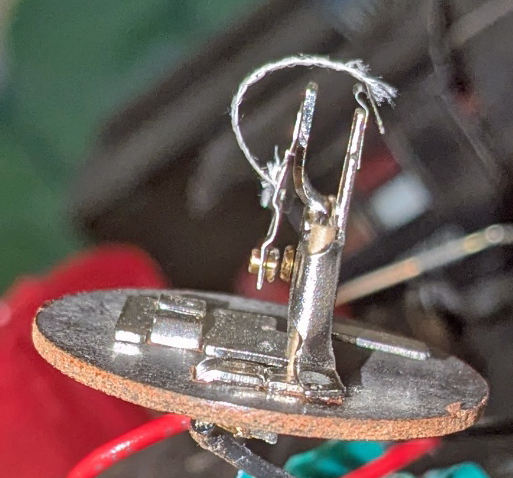

The plunger returns based on gravity pulling the hammer back down. This means the plunger and hammer must all move very freely. NO OIL on the plunger. To get the plunger out, the sides must be bent out and then bent back in later for re-assembly. The Bell Ringer solenoid is essentially and E unit. See the E-unit repair notes for maintaining the coil and plunger.

Wire connection for the Bell assembly.

Replacing a bad thermal switch.

There are no replacement thermal switches that I have found. Getting one rewound and insulated correctly is time consuming and problematic. I found the right automotive flasher can work. This 2 prong, JIN-Y1 super winker 12 v 8-23 watt flasher works well as a replacement for the thermal switch. It was for a motorcycle. I attached it with double back tape. I also taped over the connect to prevent any contact with the shell. Tabs were bent over or cut off. It only works when the solenoid is grounded.

AC works with the flasher especially at the standard running voltages of 10-14v for these small switchers. It tends to switch 20 percent faster than the original. The inside of the flasher and label.

Back to Main page.

Last Update Jan 14 2025