Notes on the MK4 and MK4S

My interpretation of the MK4 and MK4S

Last Update Sept 16, 2025

I have built 2 MK4 kits and have upgraded an MK3 to MK3.9. I

upgraded my MK4 to an MK4S. All passed setup easily and work

well. I have upgraded my MMU2 to MMU3 to use on the MK4(S).

Overall I like Prusa Research reliability with good support and a large

community of users. My MK4S prints well out of the box.

Saving a few dollars on cheaper systems may cost you thousands of dollars

in time. The 3D printing experience for me is vastly improved with

the MK4 series printers.

I have moved my MMU3 to a Core One system. Notes for the MMU

First impressions of the MK4 Firmware 6.0x

I am very happy with the MK4. It is about

20% faster overall and up to 50% with the Input Shaper enabled. My

wife notes it is quieter than my MK3S+. Vase mode printed

parts on the MK4 are stronger vs. the MK3s+

The MK4 can put reliable 3d printing into more hands. Load

filament, keep sheets clean and run, run, run. That is what I have

been doing.

There are still some minor problems with seeping of filament from the

nozzle when not running and heating. Extra retraction may be needed

at the end of a print. This is eliminated with the MMU3 setup.

USB thumb drive warning

The cheap USB sticks that come with the MK4 printer tend to have problems

and are often replaced. It is easy to get a good, quality

replacement. Make sure the new USB thumb drive is USB2,

NOT USB3, 3+ etc. Through harsh experience I learned that

a USB3 drive may cause severe problems with WIFI based file

transfers. Prusalink, Pusaslicer and Prusaconnect all had

problems with file transfer failures when using a USB3 thumb

drive. I have used multiple USB2 drives with

no WIFI based file transfer problems. Recommendations for the

MK4 USB thumb drive:

- USB2

- 32GB or smaller

- Formatted for FAT32

- Allocation size when formatting, 4096, a personal preference for the

3D printers.

Significant Details

- The Nextruder has 2 points of contact on the filament and is

stronger. It has a quick release for filament removal.

The extrude gear on the MK3s+ often did not grab the filament enough to

pull it from a remote storage, through a buffer and keep it flowing

without skipping. Happened when the filament rolls were wound

tight and "stuck" at the edges. The Nextruder will pick up a

roll when this happens and keep going until it comes free.

Happened about 5 times on one print and there were no discontinuities on

the part. Note, avoid bad, brittle filament. Brittle

filament that will not bend, but breaks easily may break in the drive

gears of the Nextruder.

- 32 bit hardware. Hopefully more functions are coming.

- Easier to use menus.

- Touch screen function added in FW6.0x

- The Z height Auto. No more qualifying and recording each

sheet. Just put the sheet on and the machine adjusts.

It only measures the print area also. First layers are

perfect. Great coverage and no gaps. 1 layer silhouettes are

possible.

- Love board shortens all the connections on the Nextruder. No

more re-threading and re-wrapping wires when a thermistor has to be

replaced. It is much faster to change out the tip, almost as fast

as the demos make it seem.

- Cold swap of the MK4 style nozzle. No more heating and

re-tightening when swapping a nozzle. If using the V6 nozzle

adapter, the hot torquing is still needed.

- PrusaLink WiFi. 2.4G max WiFi. Great for monitoring the

machine, transferring files and starting the print. Make

sure you connect to 2.4ghz login, not the 5G on your WiFi.

- Faster printing by about 20%, Much faster with Input Shaper

software. It appears Prusa-Research is beginning to understand the

compensation needs for the hardware and filament done with

software. Things the NC machining industry has already learned and

implemented in modern high speed machines.

- Better integration promised with the MMU3. 100% reliable

filament breaks are needed. For me this is the major failure of

the MK3S+ with MMU2. Some filament colors could cause the filament

break to fail, so often it was unusable for color changing in a

part.

Mods I have done for the MK4

These mods may not be a big change, but there is no downside to these mods

that I see. Making parts a little stronger/better than the default

settings also helps. Adding the parts listed to the nextruder should

not effect input shaper settings. The added percentage of weight

to the nextruder is very small. The MK4S upgrade eliminated the

need for 3 of my 4 top MK4 mods.

- MK4S upgrade has a sock! Important, Put a sock

on it. Partsbuild.com

You must tell the printer it has a sock, Enable the sock in

Settings-> Hardware-> Nextruder-> Silicone Sock.

- MK4S design change eliminates this. Important

Deflector for Heat Break fan inflow.

A good thing to have based on initial reports that state the heat break

fan may interfere with the cooling flow on the part. ASA and ABS noted

as having a problem.

- MK4S replaced this. Important Improved

filament cooling fan. Cooling air all around, no dead

spot as the original. Need ASA or other High temp filament for

printing. The original was ASA.

- MK4S has Y axis belt mount made of PCCF for better

heat resistance. Important Make

the Y axis belt mount 1 piece. Printed in

ASA for high heat strength. For better strength and reliability of

Y axis (my mod). I A new

Tensioner is also needed with this mod.

- Medium Nextruder

fan deflector for Heat Break fan outflow. Used

the V2 deflector. Works well at deflecting the air up away from

the bed. Used PETG, 0.2mm Using Organic supports on the one wall only.

To install, remove the heatbreak fan, loosen the 3 Nextruder mount

bolts just a little to allow it to snap in. Then tightened the

nextruder bolts and remounted the fan.

- As needed. Squash

Ball Feet x 6. Shorter ones for use with MMU3

that is horizontal. Squash ball feet help reduce

noise/vibration.

- Housekeeping Z axis Dust covers, the

2 piece version. Keeps filament junk from

accumulating.

- Housekeeping X

axis Cable guide.

- High Heat enclosure. Buddy

Board Cooling. See also Remixes for this, to use in a

Prusa Enclosure. If you intend to use a high temp in the

enclosure. 55C or above in my estimate. Not needed for PLA/PETG or

similar temperature ranges.

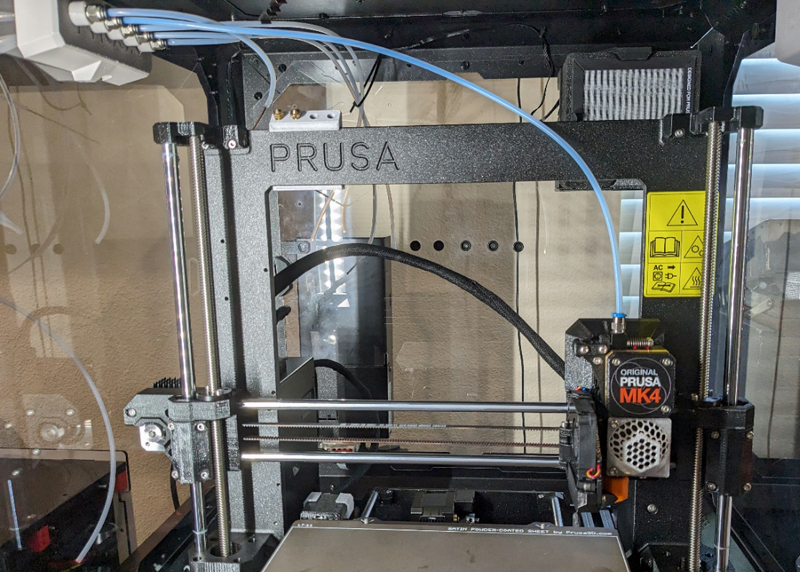

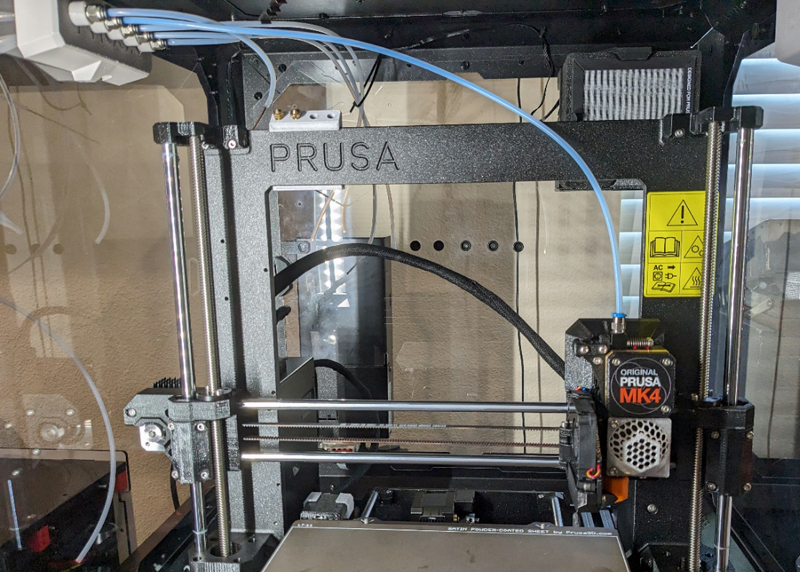

- Convenience PC4-M5 Festo Fitting and PTFE tube anchored at the

other end added. See explanation and picture below.

MMU3 has NEW festo fitting that have a different internal diameter.

- Nextruder mods for flex filaments. Non MMU3 printers

- Improved

Idler for flex filaments. This may be needed based on what

I would describe as tolerance buildup. I suggest 0.2mm

layers, 4 profiles and 30% infill. PETG or better.

High heat tends to cause this part to bend. MMU3 version

is stronger, higher heat resistance.

- For flex filaments. Nextruder

main plate mod. Helps contain the filament in the

Nextruder. 0.2mm layer, 4 profiles, 25% infill.

This is significantly fewer important mods than I had with the the MK3s+

and MMU2 to get it to my standards.

MK4 to MK4S upgrade

The fan and High Flow nozzle updates are the significant part of this

upgrade. Allowing faster printing and reduces the need for

supports. Also many parts are now made of PCCF for strength

when printing High Heat filaments.

- MK4S comes with high heat resistant PCCF Nextruder idler and main

plate parts for NON-MMU3 printers. The MMU3 Nextruder main

plate and idler updates are still used for the MMU3.

- PCCF Y axis belt adjuster parts. Seems the PETG softened and was

letting go of the belt when printing high heat materials.

- New PG cover with MK4S labeling. Cosmetic, but it does not have

the spacer my old one had. The old cover shows the spacer was not

contacting the gears so I don't thing it was needed.

- Fan update. The high flow fan and nozzle combined with the

profile updates in PrusaSlicer 2.8+ that drive it. This allows

much more overhang with fewer supports. Airflow analyzed by

Prusa.

- High flow nozzle. Faster printing in speed/draft modes.

Structural mode is not faster. Also enables thicker layers

which may speed up printing also. Older nozzles still usable.

- Updated xLCD mount with a back cover now. This encloses

the xLCD in the back preventing random items from causing a short or

failure. Maybe helping with electronic interference.

- NSF antenna. NSF active devices will pull data from the

printer. For use with the mobile Prusa printer app.

- WiFi card update. This also includes cable pass thru slots

for the Accelerometer. Accelerometer is an optional purchase.

- Sock is added for the nozzle.

MK4 vs MK3S+

What stayed the same on the MK4 vs. the MK3s+? The frame

assembly, Y and X axis rods, Y carriage, heat bed and the power

supply. The Full 4K upgrade offered by Prusa makes it a full

upgrade. All except the new lighter frame. Not a structural

issue.

You could buy a full MK4 kit and have 2 printers when done. It

could be a better value, depending on space available and your

needs. Be warned, you may not want to use the MK3 series anymore

after using the MK4.

If you are on a budget and want nearly 100% functional upgrade, I

recommend the MK3.9. Gets everything but the finer servos. I have

built one and ran it before giving it to my grand kids. It

runs the input shaper. Smoother Servos still can be added

later if desired. For most the upgrade would be great. You

print your own printable parts so don't tear the MK3x apart early if you

do an upgrade.

Some things Prusa told you about the MK4

- 10mm Rods for Z axis. Since X rides on Z, Z needs to be

stronger.

- New frame is same thickness as MK3, but honeycomb for strength and

lighter weight.

- 10mm more Z travel.

- Nextruder for feeding filament. Double contact, gear reduction

drive.

- New hot-end design and faster switch outs. Fewer joints for the

filament to go through with in the Nextruder.

- Auto Z set, Change the sheet and no re-calibrating needed.

- New servos for faster performance and smoother printing

- New electronics. 32 bit software

- Love board to help eliminate re-doing the wiring from the hot-end to

the motherboard for any hot-end changes. Changing tips, thermistors or

heaters should only take a few minutes.

- More sensors.

- Faster and much faster once they get the Input Shaper firmware into

production.

- WiFi, with web browser support. You can upload another file while the

printer is running.

- USB memory card.

- Firmware upgrades from the USB.

- 400 pulse per rev servos.

Some nice things that may not be mentioned

- Touch screen active.

- Firmware options with 32 bit system have expanded greatly.

More improvements may come.

- X axis tension adjustment uses 2 screws end to end, so the head of a

screw is against the X axis motor. This makes adjusting the

X axis tension work well. The screw head doesn't notch the motor

housing and slide out as it did on my MK3s+ originally.

- X axis mounts have 4 long screws in the body. These screws act

as the stops for the X axis rods. Better holding the distance

needed to align X axis on the Z axis screws.

- Linear bearings are fully captured on both ends for Z axis. Also

bolted covers, no press fits. Z axis is a single bearing not

2. The 2 bearings in the MK3 Z axis had a gap in between allowing

the bearings to move some.

- X, Y and Z linear bearings have a rubber mount in the bolt on

covers. I think this helps prevent squashing the bearing out of

round.

- Z axis servos have a rubber mount between the servo motor and the Z

axis mount. Some vibration control, but mainly helps you be able

to align the Z axis lead screws.

- X and Y axis idlers have a V mount for the pin. As you tension

the belt, the idler pin is pulled into the V. Once pulled in the

pin is captured on both ends. No worry about it ever coming out.

- X and Y axis belts are cut to the correct length.

- The belt tension tool you can print for the MK3S+ works on the MK4.

- Z and X axis mounts are bigger, stiffer.

- X and Y mounts have reference surfaces to aid in positioning the drive

gears.

- X and Y axis drive gears have 2 set screws.

- Y axis motor uses a thermal pad to dissipate heat through the printer

frame.

- Access to the motherboard is from the outside of the printer.

Not inside the frame where it is hard to get at and see what you are

doing. Very helpful with my big hands.

- Wire guide clips added to help guide some wires. These are extruded

plastic parts, not 3D printed ones.

- The Nextruder top is already threaded for a mount. It is an M5

thread. Use a PC4-M5 Festo fitting. The PC4-M5

Festo fitting sold by Prusa has a bigger ID than the standard PC4-M5

connectors sold. The bigger ID is needed. See

the setup in my enclosure until the MMU3 is ready. I suggest using

PTFE tube with one end held in the Nextruder and the other end held in a

mount before the filament is fed from the roll. To minimize

or eliminate Z deflection of the X axis. The default with the roll

hanging above the Nextruder and only the filament fed into the Nextruder

may cause a problem. When the filament sticks on the spool, it

will cause a Z deflection as the Nextruder pulls the filament.

With a PTFE tube anchored at both ends, the pull is against the tube and

Z deflection is minimized or eliminated.

- Most bolts are packaged based on size, not assembly operation. A

little easier to find bolts I think, if you put them all in order.

- Peep holes to assure X and Z axis rods are fully seated.

- Bent ends on the hot-end plastic stiffener cable that helps hold the

wires out of the way. Places for the bent piece in the hot end and

cabinet mount to assure proper twist and lift.

- You can easily dis-engage the idler of the Nextruder for removing

filament as needed.

- Better instructions for lubricating the linear bearings, you may still

need to wipe off excess from the rails the first few prints.

- Hot-end Wire channels are big enough to easily route the wires.

- The Enclosure remote power supply conversion for the MK3S+ will work,

but the quick dis-connect will not. 1 large ground wire

added. Early MK4's had 1 wire Power Panic, but the same 2 wire

connector on the power supply, they are back to 2 wires for power panic

as of 9/2023.

- WiFi is 2.4g max 4.5-5 mbit. File transfer speed is relatively slow,

500k bit, but it is not the WiFi that is the problem. It supports

real time monitoring of the MK4.

- Screen preview of the part in an ISO view. Copy of the slicer G

code display routine.

- 1 wire for the power panic connection, the MK3S+ had 2. As of Sept

2023, back to 2 wires.

- Extra ground wire connecting the LCD, Buddy Board and power supply.

- PrusaLink to monitor, load and run from a browser on the network.

- 5 Foot notes can be shown on the screen and may be selected in setup

by the user. Nozzle temp, speed, Z, X, Y and others.

Dimension differences of the MK4 vs MK3s+ From measuring

the MK3s vs MK4 parts.

- The Nextruder tip is 10mm higher than the MK3s tip. This

gives the extra 10mm of Z travel. 220mm total.

- The Nextruder is 64mm wide vs 50mm wide for the MK3S

hotend. The MK4 servo mounts for the Z axis lead screws are

7mm wider on both sides, 14mm total. The 10mm rod is 9mm wider on

each side, 18mm total.

- The 10mm diam. Z axis rod is 325mm long vs 8mm diam. x 320mm for the

MK3s+. The rod is held deeper in both bottom and top mounts.

MK4 13.5mm depth for rod on bottom mount and 12.8mm for the top

mount. Compared to the MK3s with 5.2mm on the bottom and

6.9mm on the top. MK4 10mm rod mounts 2x deeper overall. The

Prusa mini 10mm rod is 341mm long.

- The top Z axis mount is 4-5mm above the top of the frame.

- The MK4 Z axis servo mount is 2mm lower when the 2mm pad is

used.

- The X rods engage a little shallower on the MK4. 52mm estimated

vs 62mm on the MK3s. They are still 3 diameters deep on each end on the

MK4, this is good.

Notes on the MK3.9/4.0 upgrade: The v1 Mk3x to MK4 (full) assembly

instructions show the frame assembly, power supply, Y and X axis rods, Y

axis carriage and and heat bed are re-used when in good condition.

These parts do not change in the MK4 The Y heatbed thermistor is

changed for the new Buddy board connection. The instructions then

links you into the MK4 build at the point the buddy board is installed.

- The Z linear bearings are replaced. You will be left with

4 extra 8mm bearings that can be used as replacements as needed.

- The 10mm Z axis rods are included.

- All the MK4 printed parts are used. You get

the filament only and must print your own parts in the upgrade kit.

- The MK3.9 kit does not include new X,Y and Z axis servos.

- The aftermarket "Bear" frame should work as long as you have updated

MK4 parts for the bear frame.

MK4 V1 vs. V2/3 printed parts

Look on printables.com, in the comments on the MK4

printable parts. A user compared parts and listed the ones that did

not change and the ones that did change. Those that did not

change were still marked V2 instead of V1. Most changes appear to be

driven by the Prusa assembly group, to make assembling a printer easier

and faster.

- Many are marked as a fastener change. A relief in the bolt hole so the

bolt goes in easier. Relief in some of the square nut holes and taper in

the hex/locking nut holes to make it easier to insert the nuts.

- Some of the axis mounts are a little thicker.

- Some mating parts now have a relief area around the bolts, My guess

this helps clamp better.

- Some cable guide changes in the Nextruder assembly.

- 2 versions of the LCD covers and mounts, must be a 2nd style LCD board

now. V3 has differences compared to V2.

Some things I think should still improve, minor overall. See Software rule #16

- Y axis mount to the table. This holds the belts and also is the

bump-stop for Y axis homing. With only 1 bolt holding the back

support, it may wobble loose during all the homing. I put

longer screws in and lock nuts against the Y axis guide to make sure

they don't come loose on one build. Make

the Y axis belt mount 1 piece, my mod to solve this. .

- Software/hardware G code upload speed is limited by something in

the hardware/software. The 2.4G WiFi works well, it is not related

to WiFi speed. You can upload while the printer is

running! Since Firmware 5.1.x and Prusa

Slicer 2.7.x the G code can be compressed. It helps, but the

WiFi routines already compresses data. I don't think the loading

speed has increased much as a result.

- Build Instructions: Tighten the screws. How

tight? Especially when there are areas in the instructions

that say "Don't over tighten". I am 6' 3"/188cm with hands

that cover a soccer ball. Can you tell me a way to measure what

Prusa thinks tight is? I see in the instructions about

changing a nozzle in the MK4 heater block they now recommend using a

torque wrench!

- Build Instructions: You aren't told why X and Y axis are plugged in

last. It is to prevent damage to the board from the servos

generating power as you move the axis around during assembly. But

now the instructions show them plugged in earlier. 10/2023.

- Build: One 90 degree torx wrench has a different size on each

end. It confuses people and they don't find the correct end,

even though the instructions warn you.

- Build: Thermal pad for the Y axis motor. I had the double blue

sided peel off cover. One would not peel off.

- Build: Y axis servo uses the bed for a heat sink. X axis servo has

nothing for additional cooling. I know it gets better air

flow than the Y axis motor, but not much. I will add heat sinks to

it.

- Build:Using the frame to cool the Y axis motor. Hot spots on the

frame can twist the printer out of square.

Improvements I would like to see

Firmware: Build progress picture should show progress in Z, or have

the option to show it that way.

Slicer, support minimum move definition and then use the data to

correctly fix Z moves and XY moves.

Better XY resolution. .02mm equivalent to the Z axis.

Currently the MK4 is .08mm resolution.

Making it a better machine tool. That is a very long discussion.

Back to My 3D Printing