Lionel flat cars with trailers need bands or something to hold trailers on. When I saw trains with trailers growing up, they often had a 5th wheel connection on the flat cars . I didn't want any bands holding the trailers on. This became a 3D printer project.

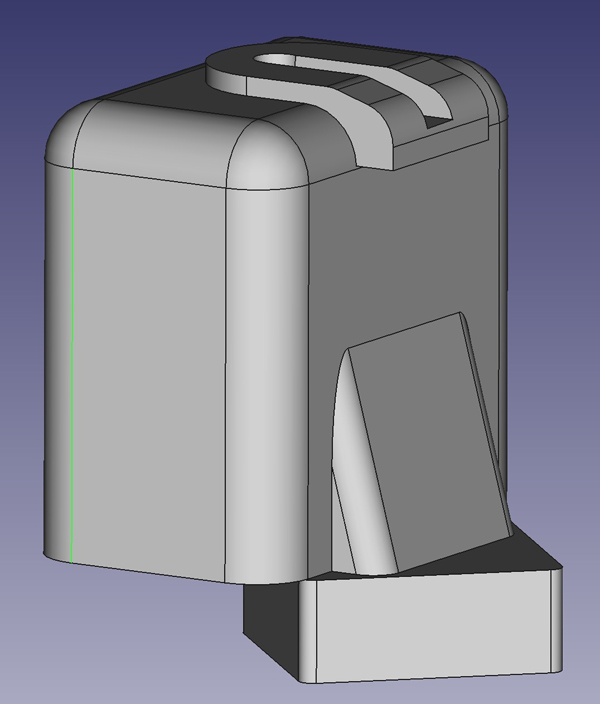

First the design. Designed for the 3460 car with the metal plate. It has nice square holes that you can use to hold the stand. I did this in FreeCad and can make changes as needed.

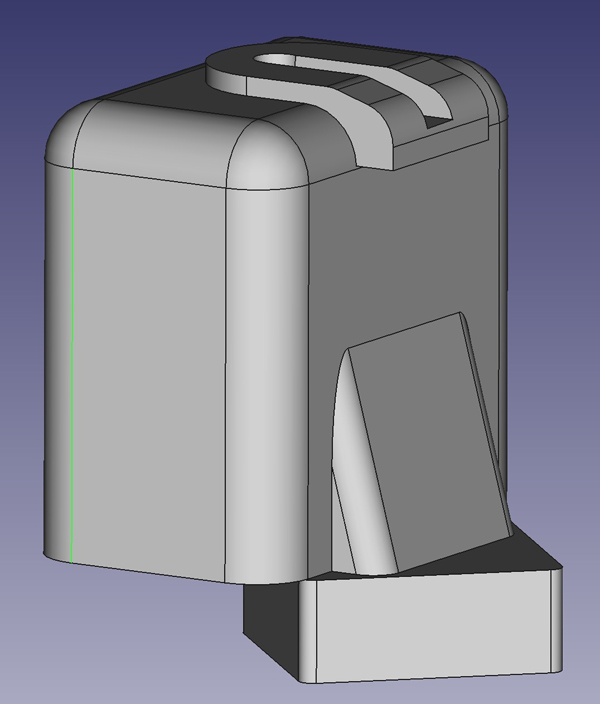

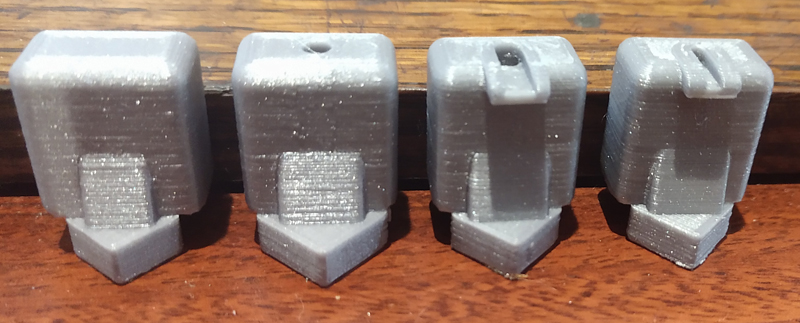

Design and test took a few iterations. To get the press fit right, adjust height and get the hole right.

The trailers have various size holes over the years. In this case I needed a 1/16" or 1.7mm hole. I found a 1/16 brad for the "King Pin". Cut the tip off and it worked well.

A little black paint. Just a little, I ran out. And press it into the hole on the trailer.

The Trailer I had been using for testing worked fine. The second one didn't A little adjustment was needed on the end of the tab that holds the parking wheels on.

After the adjustment, both trailers are on. The ride well, no more risk of sliding off the trailer. How well will it work with the trailer loader? I will have to see when I get one. Maybe one more adjustment to shorten them a little more, but that will be another day.

16330 with Trailers

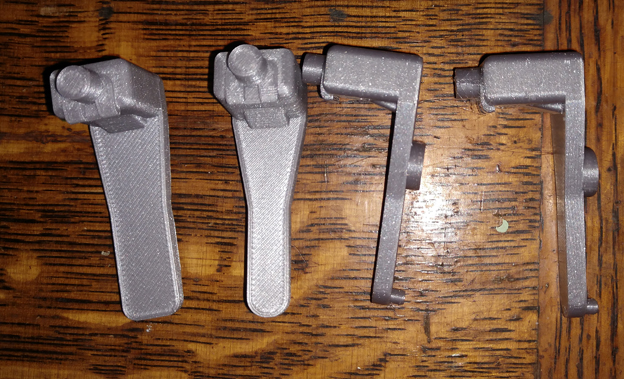

On to a more modern 16330 trailer. These trailers have a 6mm or 1/4" hole for the "king pin". There is a small hole .125" or 3mm hole in the center along with the .4"/10.16mm hole for the truck rivet on both ends of the trailer. I decide to use these holes for orientation. Also to press fit into the truck rivet hole to hold the mount in. No glue no fuss. If you want to remove it later, just pull it out with a little force.

Again, a few attempts for the perfect fit. Why so many attempts? Even though you measure, you still have to adjust for shrinkage. I modeled the large boss at .401 and it came out as .398. Modeled it to .404 to get final .401 for the press fit. The original design distance between the center of the holes was probably 1.125"/28mm on the flat car. Even the flat car had a little shrinkage out of the mold as it cooled. To get the "actual" perfect spacing between the holes took a couple of attempts. And then getting the trailer in just the right spot for the rear wheels to be held in the wheel chucks correctly. So the rear of the trailer didn't slide sideways. It was .08"/2mm variance from being too much and just right.

The final test fit. They match the color of the trailer. A little clean up and paint they will be good to go.

No more worries about stopping/starting the train too fast and having the trailers slide around. They stay on, even in a fast corner.

Back to Main page.Last Update Apr 4 2022