Part 1, 6416 Postwar car hauler and cars

The intent of these chocks is to keep the cars on the Postwar and Modern 6414 Auto-loader as it moves along the track. I found fast starts or stops tend to dislodge the cars or bump them together. Many originals do not have the headlight pieces as a result. The Postwar 6414 Auto-loader has holes punched out with small sheet metal walls all around.

Which CAD system? I have settled on Solid Edge for the maker community. Very similar to something I have had years of work with. After the first creation, the succeeding designs were easily adapted.

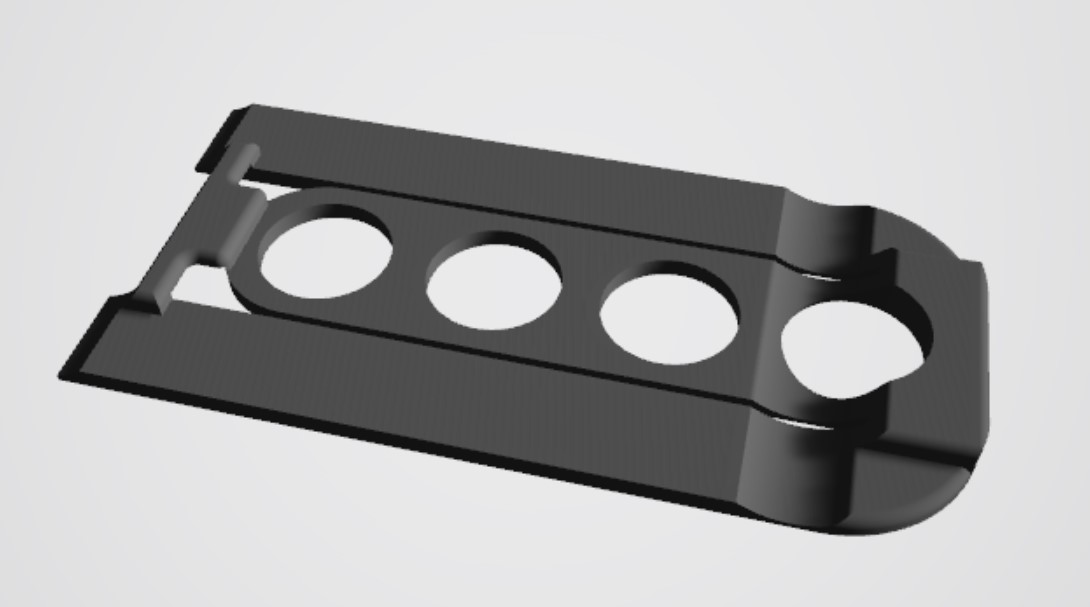

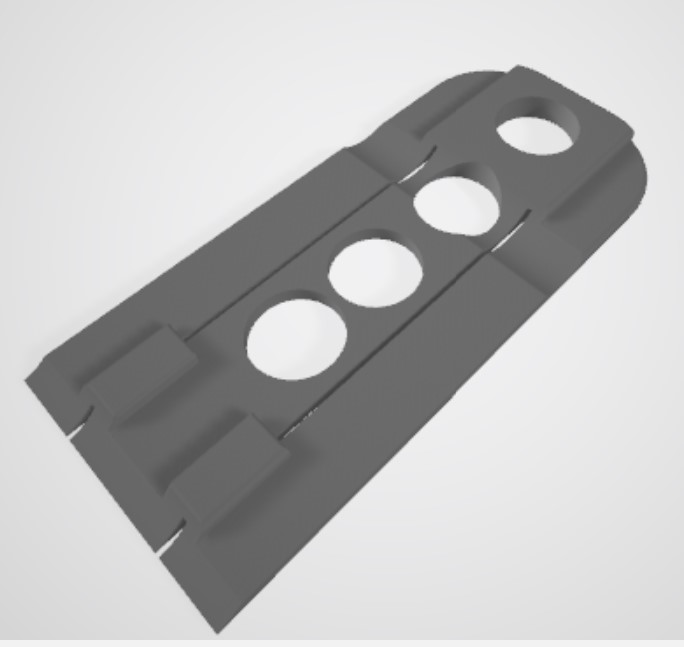

This is the final design I came up with for the original postwar style cars for the 6414 Auto-Loader. This will need to be modified for other cars based on the wheelbase and overhang.

End view from the bottom.

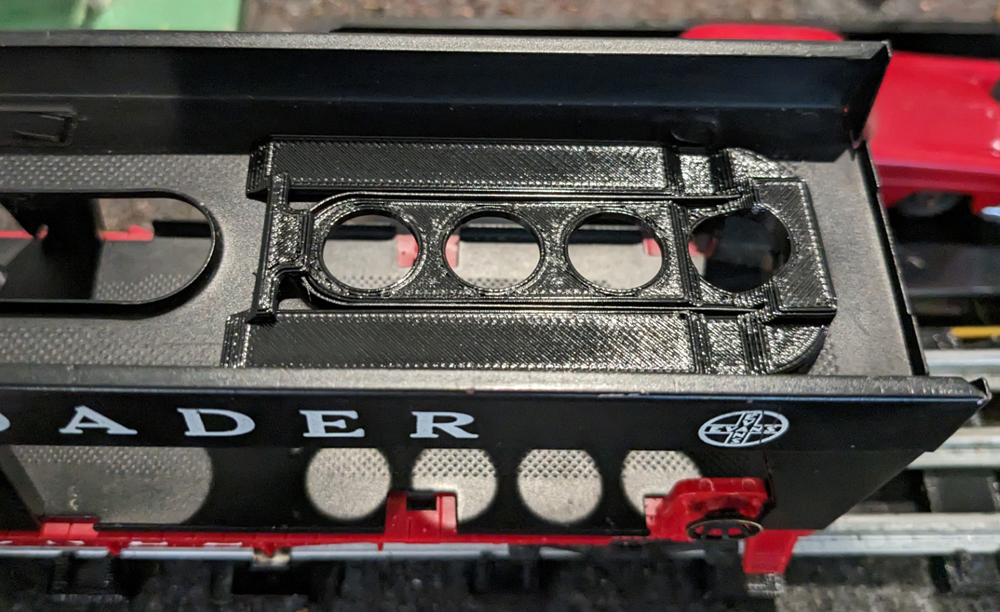

It snaps into the sheet metal holes and walls on the 6414. The round end of the chock is toward the opening on the ends. If you install it backwards the cars will not fit.

With the Cars Installed

Print with the bottom down on the plate. Supports are needed on each end. PLA works well. When using PETG, I suggest using a slicer with the Organic support option enabled. It greatly improves the ability to remove supports. I used .3mm layer height and it took 21 minutes per item. One chock is needed for each car.

Postwar 6414 car loader and cars .stl and .stp files.

Part 2, Modern Car carrier with Pickup and Tbird

I have a MKT 4223 car carrier from LOTS, Lionel Operating Train Society. It looks great with 1950's for Pickups and 1956 T Birds. I needed some wheel chocks to hold the autos on the transport.

The holes under the cars are different from the Postwar carrier. The Postwar version has a lip all the way around the hole.

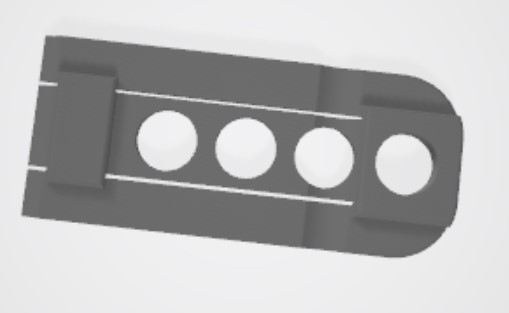

The Design for the Truck. Updated June/2023. From the top. The area for the wheels are set to the wheel base of the truck. Printed with a .3mm layer height. Black to match the Car Carrier. The area under the rear wheels is .020"/0.5mm thick. Enough for some strength, but keeps the car at original height. The front area is not to a point, but 020"/0.5mm also. The slots for the flanges are .030"/.75mm wide With 3D printers, putting radii on all the edges is easy also. A few holes to save material, but not much printing time. Cutout areas to clear details under the vehicles. Top and bottom view of the chock design. The sides were the wheels sit are kept low so the car rolls into the lower part of the carrier without hitting the top.

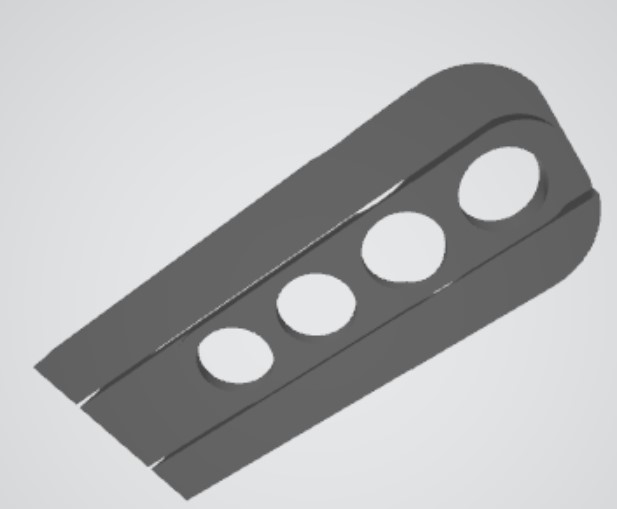

The T bird has a diffrent wheel base, needed more relief in the center to clear the "oil pan" and the oval locator is .020"/0.5mm deep so it can sit on the bottom layer. The bottom level does not have any clearance under the cutout. The bottom of the chock plate for the T Bird.

A shot with the Autos back on the Car Hauler. They stay put, no

rolling around as the train moves. The black matches the Car Hauler

and they are barely seen with the autos loaded.

No more worries about stopping/starting the train too fast and having the Autos slide around. Cars well positioned and look good. No scrapes and chips from rolling around.

Files for the modern T-Bird and Ford Car Hauler.

Back to Main page.Last Update June 13, 2023