For What Its Worth

Handy Dandy Tools, Invention by Necessity and General Ramblings

Taps Jack_Stands

Proportioning_valve_lock

Unidrill Welder

Oil_Filter_tool

What makes a good tool?

When I am helping friends and they bring out cheap tools I often tell them, "chances are I am going to bust this tool in little pieces" and usually do trying to get the first bolt/nut loose that has any resistance.Quality of the material, design of the tool and good manufacturing execution are all important. You pay for a good tool once, you pay for an inferior tool everytime you use it.

In school many years ago I did an analysis of tools for a class project. Cheap tools vs brand name. Some of the cheap tools had a lot more "good" alloys in the metal since many came from where the alloys were cheap. Fit on the bolts was much looser than the better tools. Leading to stripped bolts or letting go.

The finish on the tool and fit in you hand can make using the tool pleasant or painful.

How the tool is made makes it strong and tough. Too many people just see how shinny it is.

Continued control of the manufacturing process can lead to consistent quality and customer loyalty.

Am I worried about tool manufactures moving to "cheaper areas"? In many cases yes. Manufacturing is the complete culture. Suppliers to sales make the company. Too often management publicly states moving production is to "reduce costs". I think it is often done to cover their lack of capability to run a manufacturing organization. It shows up later when the company still goes out of business.

Taps

If you are working on old cars the most useful tool I have found is a set of good taps. Ones that can chase a threaded hole. Get all that rust and gunk out. It is amazing how much easier things go when the bolts go right on in.Jacks and Jack stands

The most important tool of all is good jack stands, 4 of them. Not 2 good ones and 2 not so good, or 3, but 4 good ones. And the wheel blocks. Your life depends on them.A Good floor jack is important also. It saves hours of cursing and frustration. Make sure it will lift more than you need. The wheels must roll easily also. Why? If you notice when floor jacks lift they also move the jack point a little forward going up and back going down. If the cars wheels have brakes on, in gear/park, chucks or the other part of the car is on jack stands, the jack MUST move. If it wont roll something will slip. It may be the car off the jack or jack stands etc. I don't care who makes the jack, never trust you life and health to a jack, greasy goo on the jack point, and all the other things that go wrong, use jack stands.

Proportioning valve bleeding tool.

If you have a stock style brake proportioning valve block with the warning light/safety switch on the car and ever attempt to bleed the brakes by using your foot on the pedal, you need a special tool. You take the switch out of the block and replace it with a tool that wont let the switch move. If you are smart you buy the thing in advance, if you can find one.. It is dirt cheap and worth it. It keeps the valve from setting in the warning/low pressure position if you get a little heavy on the brakes. Resetting it usually involves loosening a line etc. Prevention is way better than cure.If you are like me and forgot you don't have every tool that used to be in the shop you worked at years ago and you need it now! What do you do? Simple, you make one from left over fittings and a flat head 6 penny or so nail. Cut and grind nail to length and you are done. Sorry, if you don't have the right fittings, just buy the tool it is cheaper and easier! Also if you make it too long or tighten too much, you could bend or cause the valve to be siezed. Then the switch will not work as intended. Always be careful with brakes.

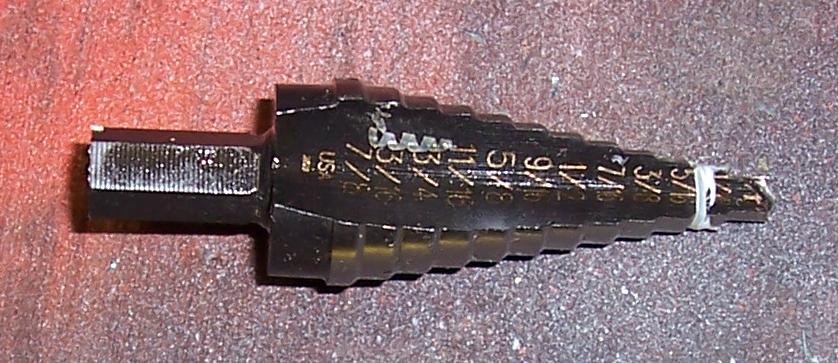

Unidrill for Sheet metal and Plastic

When you have to drill holes in sheet metal or plastic, there is a great one-drill does many tool. It is called a Unidrill. Put it in, drill the hole and when you get to size you want stop drilling. This one goes from 3/16 to 7/8 in 1/16 increments.

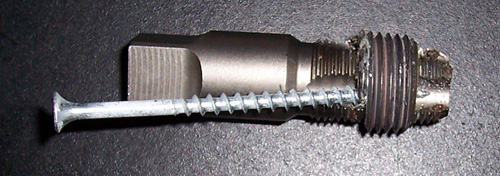

Home made pipe thread adapter extractor

What do you do when you pull the temp sender unit out and the 3/8-1/2 adapter stays in the intake and you need the adapter out? Well brass to steel does not stick as much as steel to aluminum so 9 times out of 10 the adapter stays in the intake. After some thinking This is what I came up with. Luckily I had the right size pipe tap that fit snug in the adapter. Then knock in a wood screw in the fluted area to lock it in. Apply some heat to the intake around the adapter with a small butane torch, cross fingers and turn tap to remove adapter. Out it comes. It looks like this.

Welder 3/2011

Saving money is a good thing when it also keeps the wife happy.

My wife is happy with window blinds we purchased with the cost savings.

I needed a good MIG welder that runs on 110v. Many are sold in building supply stores. After investigating the welding supply stores I found the building supply welders were not the same as the similar name welder in the welding store. Same names, different model numbers. There were in my opinion significant durability differences. My goal was for a good welder with commercial grade durability. So I set out on the long term search. I had given up on finding a used one in the classifieds. I was ready to buy a new system, with gages and a gas bottle. Around $950 U.S. I took one last look before heading off to the store and found a Miller SideKick for $100. Older, yes, but checking with the welding supply, no problem in keeping it running if it needed something. It came with a home made stand, argon gas connections and a large full roll of wire ready to go. It worked. With a gas bottle, new tips and a heavy duty 15ft/5meter extension cord I was ready to go for less than 1/4th the new price. All it needed was minor repair on a cooling fan. I also removed 2 lbs. of mud-dobber nests. It had been kept in a not to well sealed garage. On to practice my welding skills and then attack a few key areas of sheet metal on the Chevy II.

Oil Filter Wrench

Best kind of oil filter wrench. This will take off ANY stuck oil filter.