For What Its Worth

Hooker Super Comp Headers

For years I had the Headman headers on the car. They were good, but had a couple of problems. The set I had barely cleared the Rack and Pinion steering and the exit at the bottom of the car wasn't level. These were some older Headman's, don't know how well they match newer ones. Minor problems, but when I bought an off the shelf exhaust system, I found it had been designed for full length headers and the Headman's were a little short for full length headers. More like 3/4 length. I had some 1 3/4" Hooker Super Comps 2243s that had a little shelf rust, so I decided to put them on. Overall I am pleased, but there are some things you need to know.

No problem with the driver side being installed from the bottom. The instructions say the passenger side installs from the top. Well for me it wasn't going to happen. Plugs out, lines out of the way and starter off. I didn't see any way to do it. It worked easily from underneath once the car was high enough with the starter off. High enough is having the frame rails more than 25" high off the ground. How high was it, sorry didn't stop to measure. Probably around 30" You have to get the header collector pipe almost vertical and it goes up from the back side of the engine and then pivots over 90 degrees and goes right in place. If you have a lift you should be set.

How well do they fit, good but some things are very close. Looking closely at these headers they are designed to be "Narrow", the pipes are lined up vertically as much as possible giving more room side to side and in the front where needed.

As far as header bolts, pretty good access, but no header is perfectly easy. You have to know that the two bolts that have the header pipe wrapping around need to be started and most of the way in before you start tightening the rest of the bolts. My bolts have 3/8 wrench heads. I have a couple of wrenches that help me to work on header bolts. Still patience is your best tool with header bolts. The passenger side rear was the trickiest. Not enough room for my wrench to get any rotation and 3/8" drive sockets were too big at the connection and ran into the fire wall or header. Finally I used a 1/4" drive skinny 3/8 socket with an extension and ratchet.

My header wrench, 7.5"/190mm long, 12 point and tough. It is slightly ground on the outside of the box end for clearance. Good for tight places and can torque the bolts as needed. For the bolts a socket wont reach.

There is plenty of clearance for the steering shaft on my Rack and Pinion now. Looking up from under the car.

A short oil filter will work with a stock style pan. The old style long filer wont clear. Also if you have an oil pan with a kick out on the driver side, you probably wont be able to get the oil filter off. May need a remote filter in that case.

My starter had a problem. It is an aftermarket one with a rectangular block that bolts to the engine. It can be indexed so the motor can be in various positions. Also the mounting block allows use on 153 (smaller) and 168 (larger) tooth fly wheels. Originally I had the starter motor oriented up, with the battery cable mount on the outside. This orientation would not fit with these headers. I indexed the motor down, with the battery mount inboard.

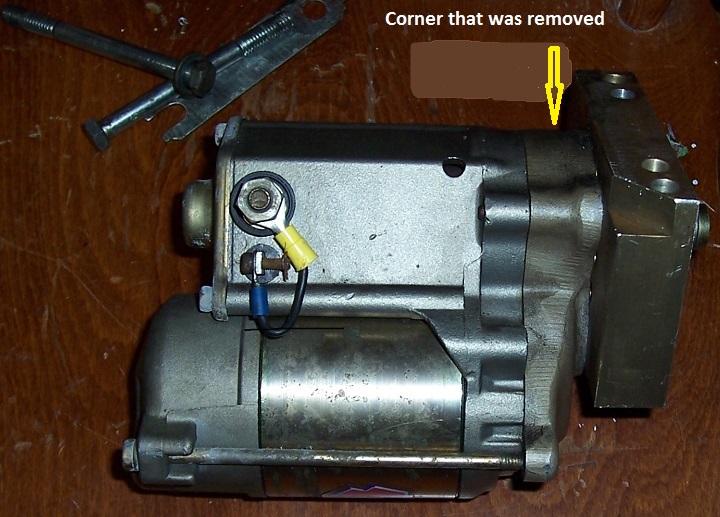

One corner of the mounting block still hit the headers just enough. I had to cut a corner off the mounting block. This cut was from the inner edge of the outboard, unused bolt hole. Done at a 30 degree angle to finish and come out in the middle of the block. A little hack-sawing did it. A triangular piece was cut off. The starter mounting block was designed for big (168 tooth) or small (153 tooth) flywheels and mine is the big one. The outer holes are used for the small flywheel, mine used the inner holes. This pushed the mounting block out a little farther than stock clearance. The one corner you can't see in this picture is the one I had to relieve.

The jumper on the starter is for using the starter with a remote solenoid switch.

Picture of the piece cut off

I have a 700r4 automatic transmission. The headers clear, but only about .1"/2.5mm at the one side of the bell housing. The picture makes the relief cut on the starter look square, but it is really at a 30 degree angle. It was the only camera angle that worked well for the picture. The cut started just at the outer edge of the washer. Removing the corner let the second header pipe clear, the one most visible in the picture.

Looking from behind the starter when bolted to the engine. The wire connecting the solenoid to the motor clears the headers, but just barely. The corner I cut is the lower left in the picture, the one you can't see.

The distance to the passenger side shock tower is very close. It clears, but you better have good motor mounts and no sag.

Driver side, no problems, it has a lot more room. This picture doesn't have the oil dipstick installed yet. I had a fancy aftermarket one with a braided body and a nut looking thing at the block. It wouldn't fit. The headers are only designed to clear a stock style dip stick tube. I got a stock style one and it works.

The headers will be the lowest thing under the car. Shouldn't be a problem on normal roads. Those with the 2" drop font ends may need to be a little more careful.

Back to the 66' Nova page