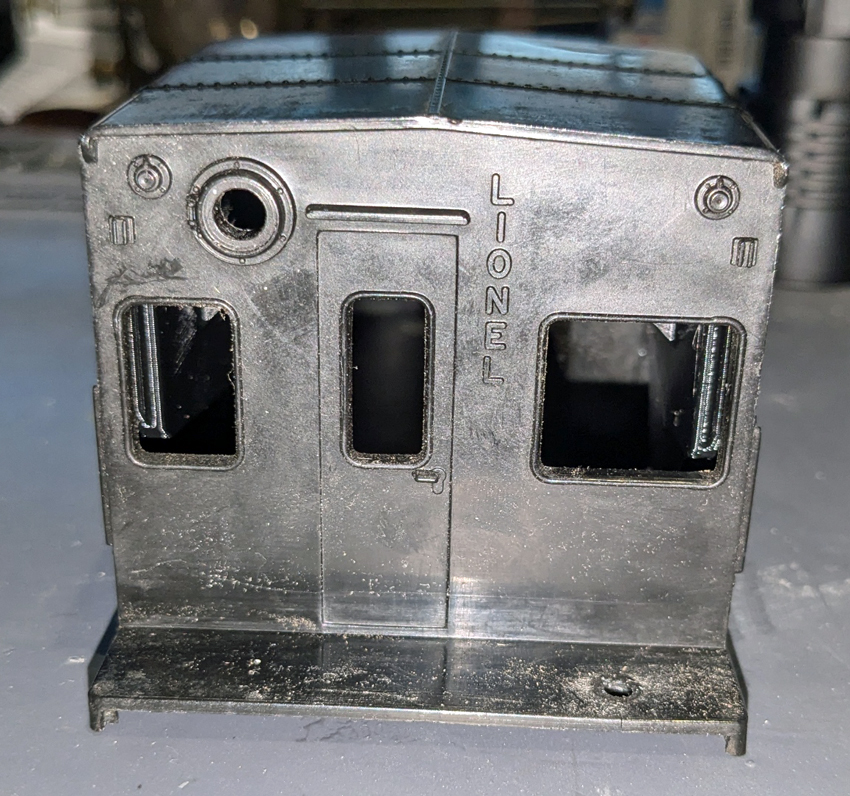

Post War Motorized Unit Window

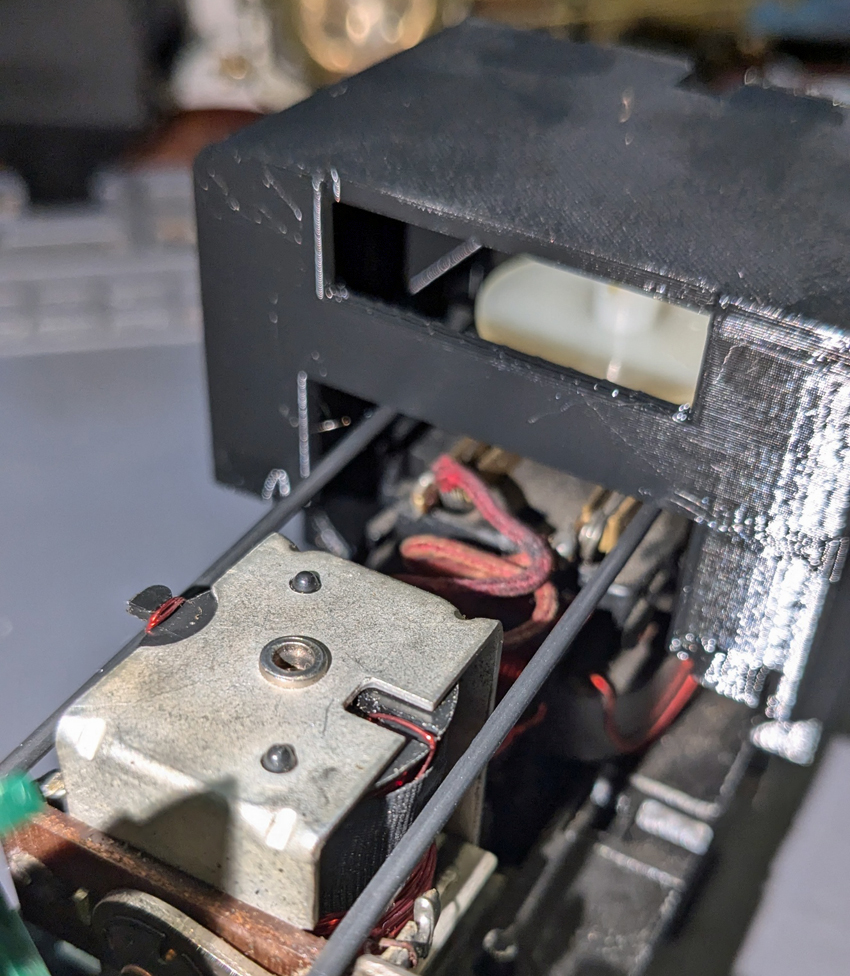

Strut Saver

5 of the Lionel motorized units have a thin window strut that is easily

broken. 3 others have multiple window struts that may still be

broken. Many do not understand these units should not be picked up by

grabbing the sides. Picking them up this way can break the window

strut. I even forget and start to pick these up from gripping the

side.

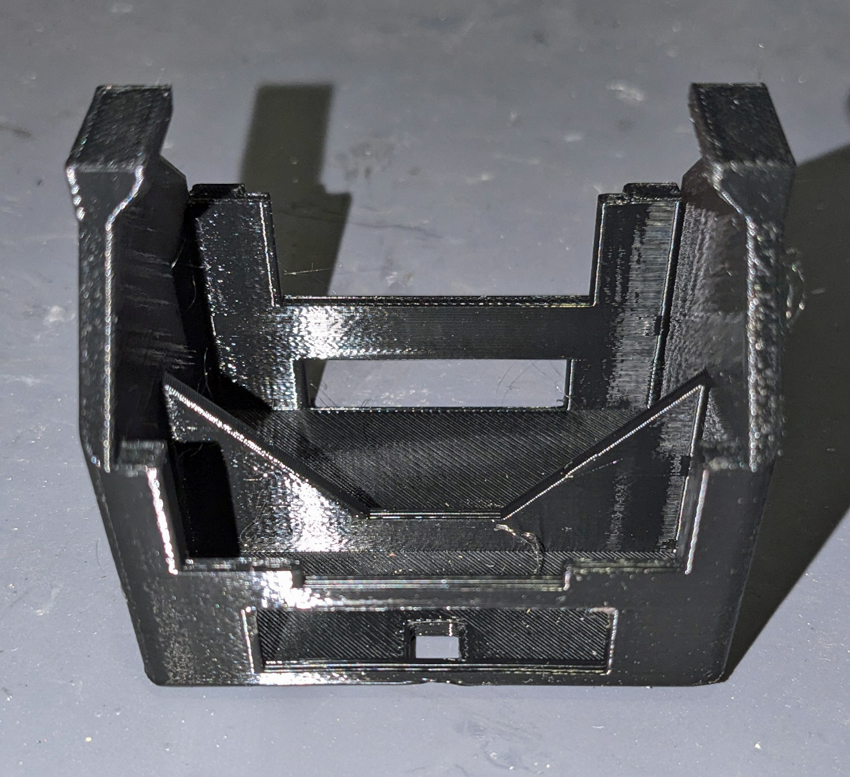

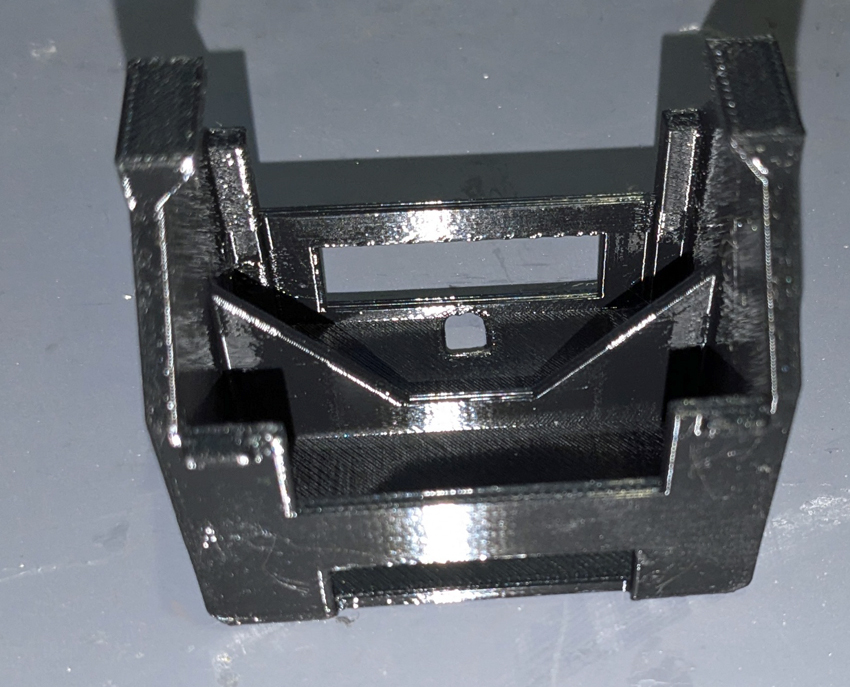

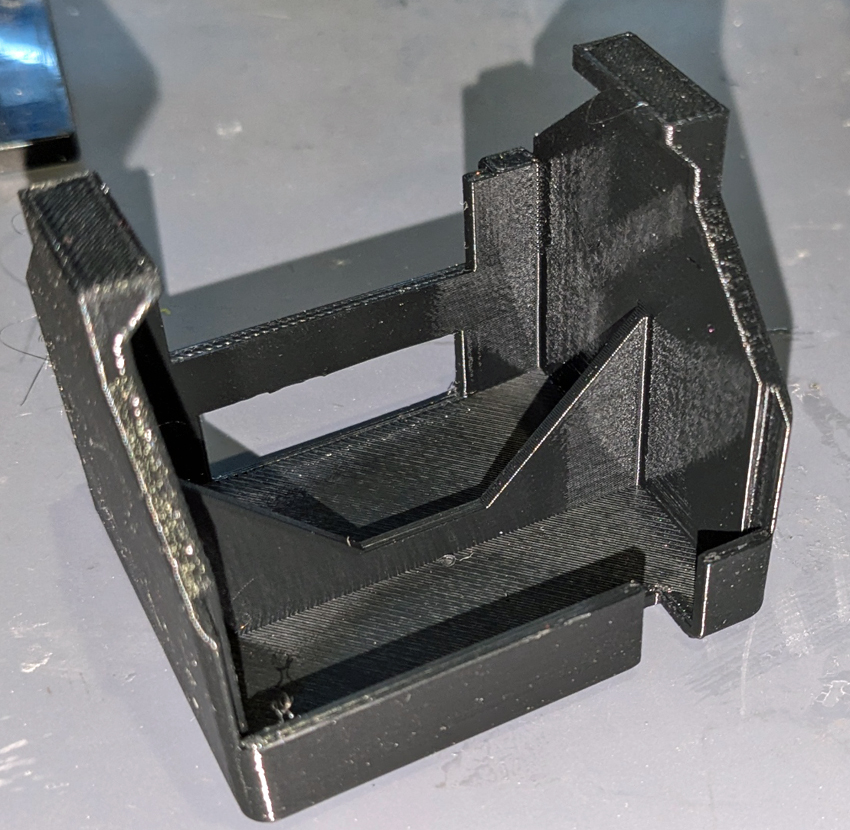

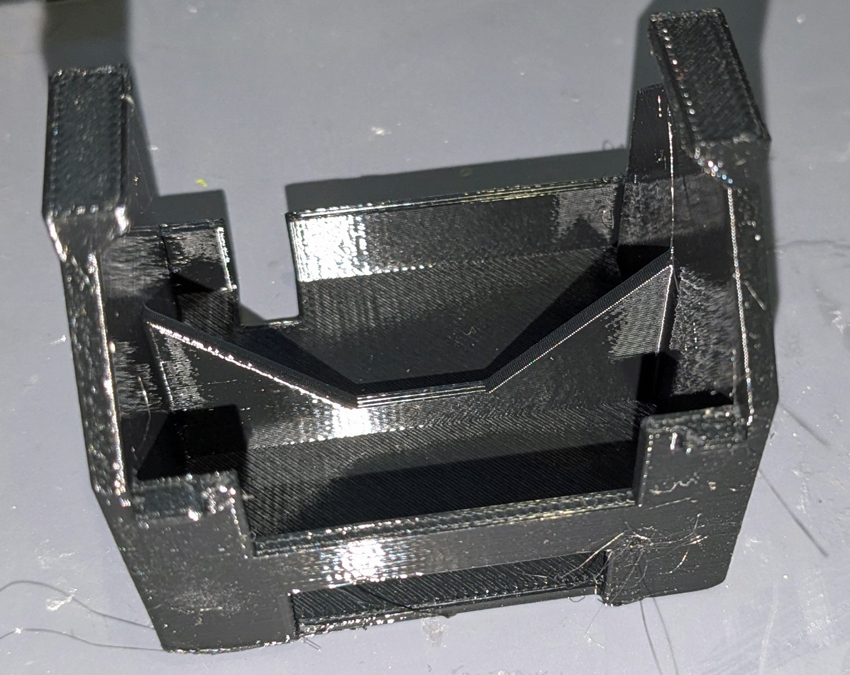

I have made a 3D printed brace that fits inside the shell and supports the

side and window area. One design for 51, 53, 56, 57 and 58 units and

one for 41,42 and 59 units.

- There are reliefs for the lights. The relief allows using an

LED light for the rear light.

- The front and back top windows are not covered. This is to vent the

heat from the motor. I did not want to make a hot box that would

cause other problems.

- There is a draft on the sides to match the draft in the units.

Many adjustments were made to fit the reliefs and supports on the

inside of the body.

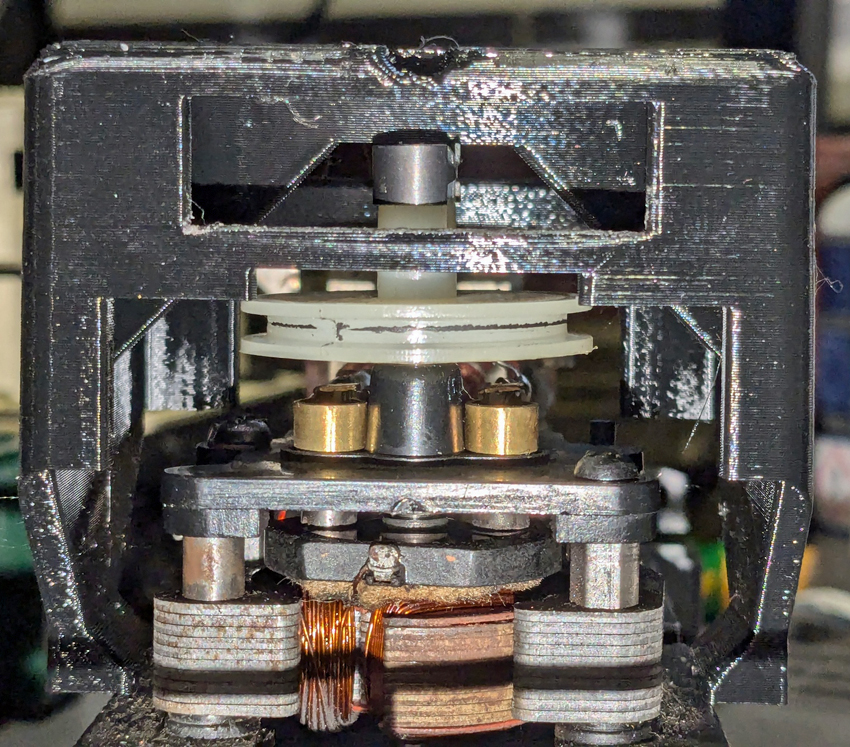

- There is clearance for the pulley and belt in the 58

unit.

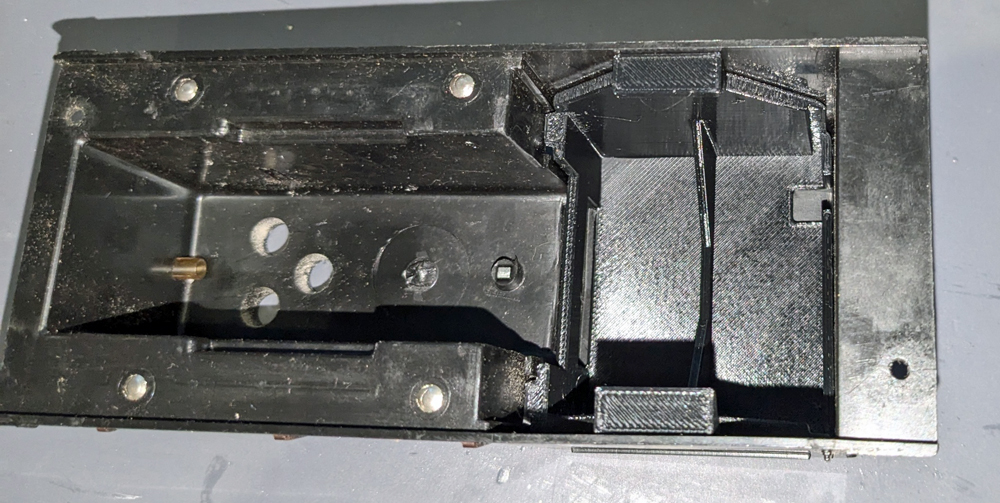

- To assemble install in shell, then put the shell on the

frame. The light relief notch goes to the back of the

shell.

Printed in black or dark gray it stays in the background. Pictures

of an interior could be pasted on the sides that cover windows to add

detail to the engine. If this is done, adding an interior light and

printing in a clear or translucent color could add a lighted

interior effect.

The files are in Millimeters.

These may work with some modern shells, but

not with TMCC enabled modern reproductions. The modern shells have

strengthened the struts.

vhubbard-window-brace-51.stl

and

.stp are for the 51, 53, 56, 57 and 58 units

Not all pictures show the final version with the notch in the back for

pulley clearance.

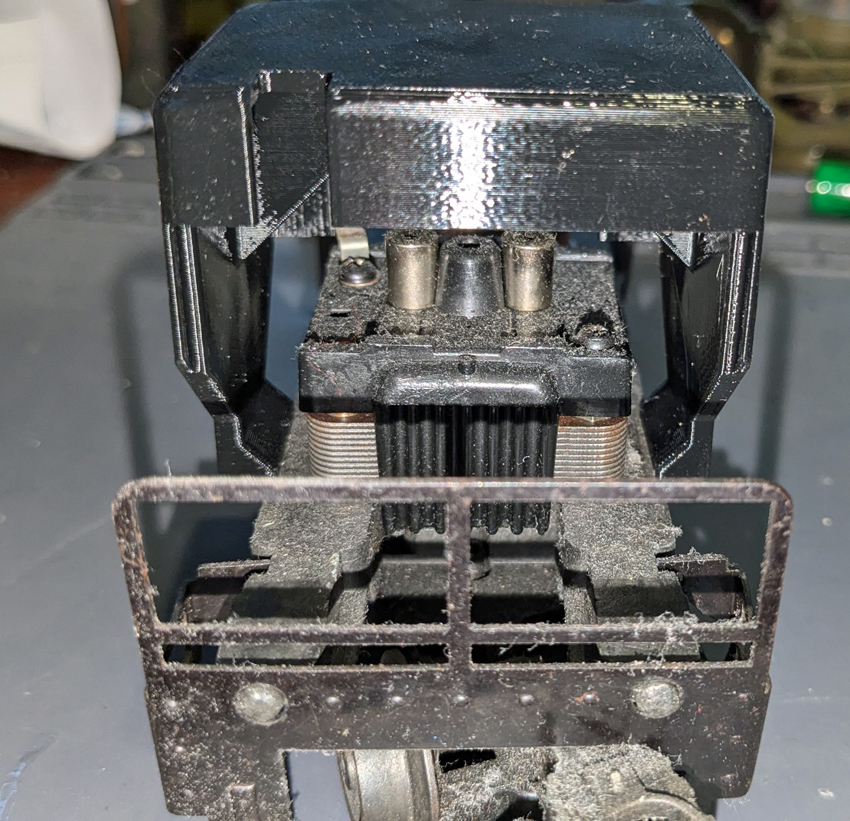

Used with a 58 unit

.

This rotary snow plow was not designed to run backwards, but if it is

run backwards the armature will move up. If more than .060”/ 1.5mm when

reversing, the pulley may drag on the shell itself.

You will need to add spacer washers to the

top of the armature, under the brush plate to limit the movement of the

armature.

vhubbard-windowbrace-41.stl

and

.stp for 41,42 and 59 units.

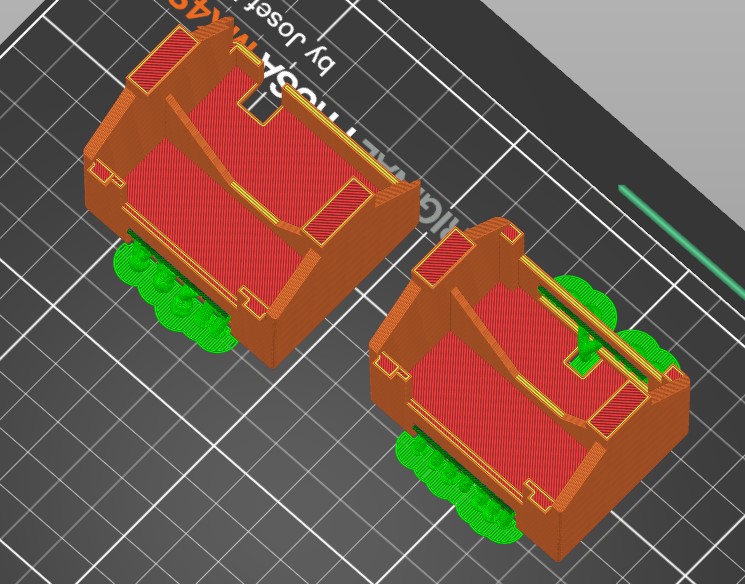

3D printing

The top of the part is down against the print sheet. 0.2mm or smaller

layers so it looks smooth in the window. vhubbard-windowbrace-51 has

2 ledges that need supports. vhubbard-windowbrace-41.stl has one ledge

that needs supports.

The rest will print without supports when oriented as shown.

This is a tight fit. These may print wider/narrower depending on the

printer. I used a Prusa MK4S. Scale if needed.

.2mm/.008” may be the difference between dropping in and being too tight

on the width.

I used PETG. PLA should also work well.

Free for private use. All Rights reserved for commercial use.

These project .stl and step files I created are

available

on the OGR

3D printing Catalog.

Back

to Main page.

Last Update Oct 28 2024