Postwar Giraffe Car, 3376, 3386

The

lionel Giraffe cars were plentiful, fun for kids but a bit of a problem

to maintain.

The

primary maintenance problem was the cam follower

The

Cam follower is often broken or cracked. It stuck out

and was easily snagged. Many that are still available are

fragile from age. I was able to design a replacement that

can be 3D printed. I used PETG and .1mm layer height and 3

profiles. The pivot pin fits in nicely and the serrated part

of the pin holds it in.

Comparison

of the original Cam Follower (Cracked and bent ) to the new 3D printed

one on the right.

With the 3D printed version I did not have concerns about draft

angles. Since there are hollow spaces in the 3D printed part I could

make the re-enforced areas thicker without adding weight. The 3D

printed part acts like the old one and clears wheels and other areas as

the original did. The pivot pin and 2 circular end clips are re-used

from the original.

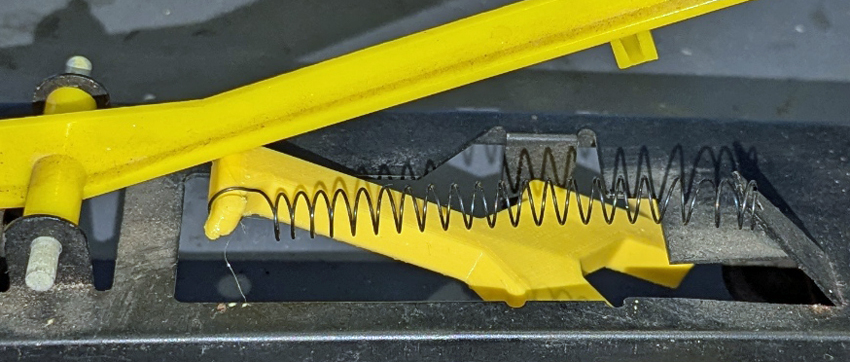

3D print

files Giraffe-follower .stl and .step I used PETG

and .1mm layer heights for proper hole sizing and bottom radius detail.

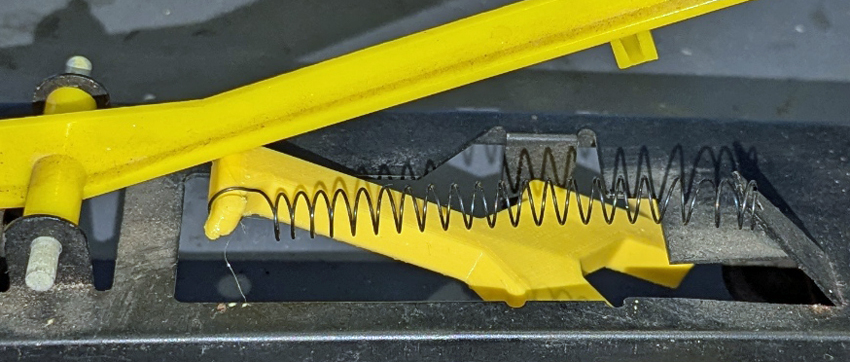

Another

problem is the cam follower spring. 3376-26

Many

of the springs broke or rusted. Some cobbled together replacement

springs but they may not work well. If the spring is too stiff, it

may overcome the spring on the CAM Plate assembly along side the track

and not get full retraction. The right spring is

critical. In this picture the spring is not correct. It was

before I could get the correct spring.

Make sure the Giraffe bar is in good shape

Make sure the contact point on the Giraffe bar is smooth, no dents or

catch points.

The pivot bar should move freely in the Giraffe bar and the metal pin

holders. The pin can easily fall out when the shell is removed so be

careful. There should also be a weight in the end of the bar, to cause the

Giraffe to go up. It is real easy to push the Giraffe down and

lock it in place. If the locking tab is about 1/3 of the way

from the head. If broken off, the head will not lock down.

The

car itself may bee too light

The

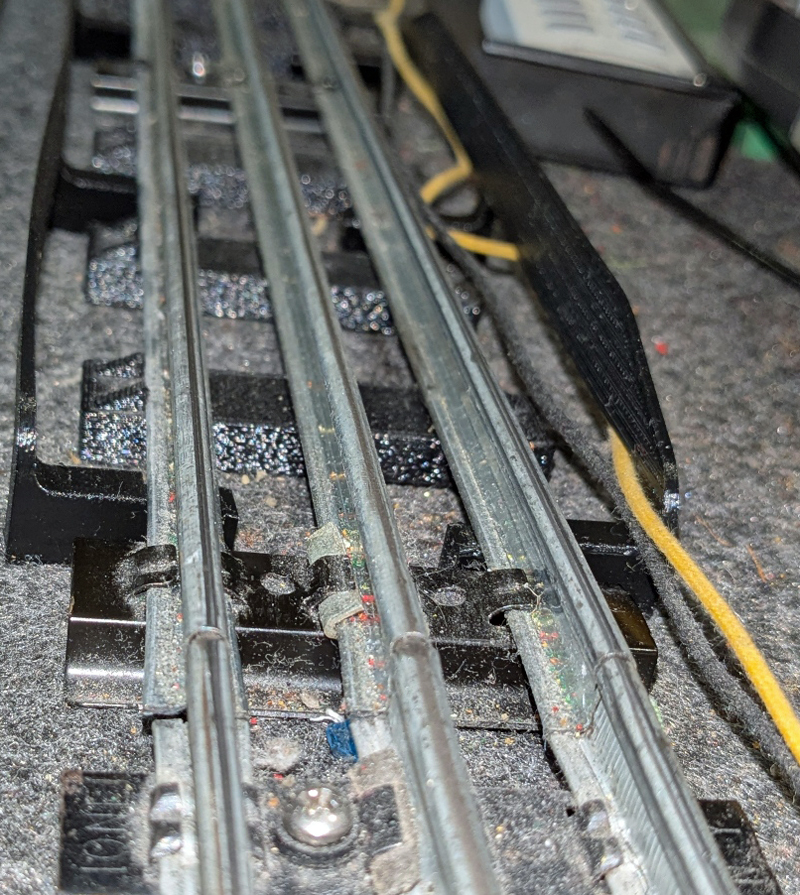

car tends to rock side to side. With the Cam Plate on one side of

the track, it may rock sideways going over and not get full

retraction. Light cars usually need weight added when

heavier cars follow it. I added 2oz of weights to help

stabilize the car and keep it on the track in a long train. Make

sure you do not block the screws that hold the body on and make sure all

the mechanisms clear the weights.

My Mods for the Giraffe Car

The

Cam Plate is spring loaded and will compress when wide Diesels or when a

steam engine with low linkage goes by. While this is a good

workaround to activate the Giraffe car and allow larger engines through,

I did not like the Idea of my linkages on some engines hitting the Cam

Plate.

I

designed a lower, slightly wider cam plate for 3D printing.

It clears all my steam and diesel engines and there is a little flex to

allow something a little wider or variances in tolerances.

It was done with PETG and .1mm layer height. This one is for O

track, not the lower O27. In this picture I have it on

both sides of the track.

Along

with this I had to adjust the Cam follower on the Giraffe car so

it would ride a little lower. I removed the raised contact on the

one end. About 5mm/.2" difference. This dropped the

follower about .1" in the front, allowing it work with my lower Cam

Plate actuator. Many of the pictures above show the Cam Follower

with the lowered end.

Lower cam follower going across the

modified actuators.

The

Giraffe isn't all the way down, but good enough for what I

want. Step files are included if you want to modify

the follower. If lowered too much There may be other track

side accessories that may not clear.

I

used PETG and .1mm layer height and 3 profiles.

Last update Nan 22, 2025